Straight hole magnets and countersunk hole magnets belong to the type of magnets with holes, they play an important role in a variety of industrial and daily life applications, today this article will take you to understand the two of them in the structure, production process, use and installation of some of the differences between the two, there is a need for quotations, machining samples remember to contact customer service MM.

Difference in structural design;

Straight hole magnets usually have one or more straight-through holes, so that it can be installed through these holes, fixed or connected to other objects, the hole can be in the front, center or side, etc. Any position, this design makes the straight hole magnets in a variety of fields are widely used, such as electronic equipment, magnetic adsorption device, and so on.

Countersunk magnets, on the other hand, usually have one or more recessed screw holes with a tapered angle from the open end to the bottom, allowing for a more secure fixing or hidden installation. This design is commonly used in woodworking, furniture making, windows and doors, machinery and equipment, and salvage, providing a solution for aesthetically pleasing and secure products.

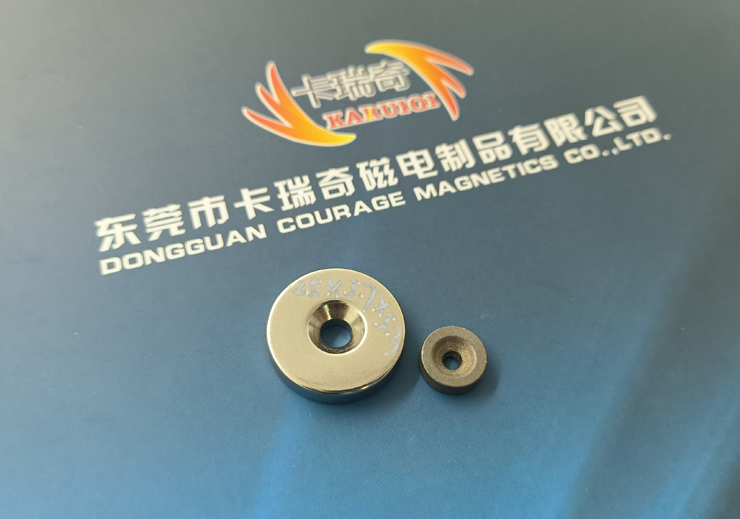

The following pictures show the type of countersunk hole magnets, the materials are NdFeB (large) and SmCo (small).

Difference in application;

Straight hole magnets are suitable for applications where a shaft or rod needs to be passed directly through the magnet.

Countersunk magnets are more suitable for applications that require a more secure fixing or hidden installation.

Differences in manufacturing processes;

Ordinary straight holes are simpler, countersunk holes need to be processed on the basis of through holes, so countersunk hole magnets are slightly more expensive under the same circumstances.

Difference in assembly method;

Straight hole magnets are usually installed by fixing them directly into the holes on the surface or other objects, which is simple and direct and applicable to the installation needs in various situations.

Countersunk hole magnets need to be assembled by cooperating with screws, commonly used screws such as M3 and M4.

The above is about straight hole magnets and countersunk hole magnets some of the differences between the introduction, need to buy straight hole or countersunk hole magnets can contact us, can meet your various shapes, performance and other customized needs.

Introduction to related magnet issues;

Why ring neodymium magnets need to process countersunk hole shape?

What are the differences between round magnet with hole and without hole

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier