Motors with permanent magnet rotors are mainly permanent magnet motors. Compared to traditional electrically excited rotors, permanent magnet rotors do not require an additional excitation power supply, eliminating excitation losses and significantly improving the overall efficiency of the motor. The following are a few typical types of motors that utilize permanent magnet rotors.

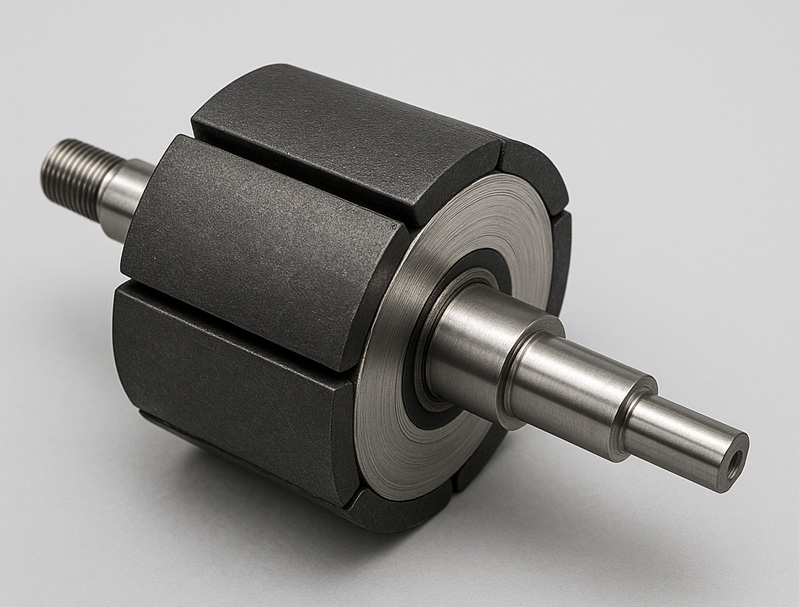

The accompanying picture shows the permanent magnet rotor assembly

The first type: permanent magnet synchronous motor

This is the most common and widely used type of permanent magnet rotor motor. The rotor consists of permanent magnets (such as neodymium iron boron, ferrite, samarium cobalt, etc.) that produce a fixed magnetic field. It is characterized by high efficiency, high power density, high torque density, good dynamic response and wide speed regulation range. Applications include electric/hybrid vehicle drive motors, industrial servo drive systems, household appliances (e.g., inverter air-conditioning compressors, washing machines), wind turbines (partially designed), spindles for CNC machine tools, robot joints, and so on.

Motor Type 2: Brushless DC motor

BLDC motor is also a permanent magnet synchronous motor from the structural point of view, and its rotor is also a permanent magnet. The main difference is the control method and the reverse electromotive force waveform. They are widely used in power tools (drills, chainsaws), drone/model airplane motors, fans/blowers, computer cooling fans, household appliances (vacuum cleaners, blenders), electric bicycles/scooters, and so on.

Motor Type 3: Permanent Magnet Stepper Motor

The rotor uses permanent magnets and rotates in a stepwise manner in conjunction with the excitation coil on the stator. Mainly used in printers (inkjet, laser), scanners, CNC machine tool feed axes, robot positioning, instrument pointer drive, automation equipment and other situations that require precise position control and low speed.

Motor Type 4: Permanent magnet synchronous servo motor

This is the most widely used type of servo motor with permanent magnets on the rotor and rare earth permanent magnets (e.g., neodymium-iron-boron NdFeB) built into or surface-applied to the rotor.

Currently, the most central and widely used permanent magnet rotor motors are permanent magnet synchronous motors (PMSM) and brushless DC motors (BLDC).

Magnets for motor rotors;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier