Most people encounter 4-pole magnets in ring or hollow cylindrical shapes. But can disc-shaped magnets be made into 4-pole magnets? Today, Xiao Fu will address this question for you.

The so called 4 pole circular magnet refers to four magnetic poles distributed on the plane or side of a circular magnet, arranged alternately, and achieved through multipole magnetization technology. It can be single-sided 4-pole or double-sided 4-pole, mainly used in the fields of motors and magnetic sensing.

From a material perspective, ferrite disc magnets are highly suitable for 4-pole configurations or even higher pole counts. Ferrite itself features low coercivity and easy magnetization. When paired with multi-pole magnetizing fixtures, it reliably achieves stable 4-pole magnetization with excellent pole consistency and relatively low cost. Consequently, 4-pole ferrite disc magnets are widely adopted in small synchronous motors, fan rotors, meters, and magnetic sensing applications—particularly suited for scenarios demanding cost efficiency and corrosion resistance.

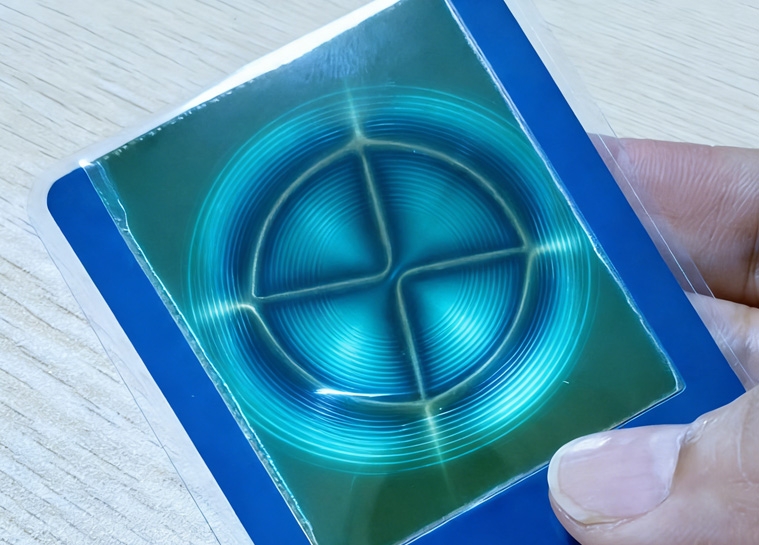

Picture of magnetic pole distribution of 4 pole circular magnet

Neodymium disc magnets can also be fabricated into a 4-pole structure, offering even more pronounced advantages in magnetic performance. With high remanence and high magnetic energy product, neodymium-iron-boron magnets deliver higher surface magnetization and magnetic field gradient for the same dimensions, thereby enhancing sensor resolution. However, due to its high coercivity, neodymium iron boron magnets demand more sophisticated magnetizing equipment. Four-pole magnetization requires higher-precision magnetizing molds and stronger instantaneous magnetic fields; otherwise, it is prone to inter-pole unevenness or localized under-magnetization.

In practical applications, the choice between ferrite or neodymium 4 pole disc magnets often hinges on balancing performance and cost. For high-temperature environments, ample space, and cost-sensitive scenarios, ferrite 4-pole discs offer a more reliable solution. When prioritizing miniaturization, high output, or high sensitivity, neodymium 4-pole disc magnets are the preferred choice.

Therefore, a 4-pole configuration is perfectly suitable. Should your company require circular/ring/rectangular magnets with additional poles, please contact our sales representatives for a quote and to request samples of similar dimensions.

Related 4 pole magnet products;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier