In motors, sensors, encoders, and automation equipment, magnetic rings are extremely common key magnetic components. Based on forming processes, the industry most frequently mentions sintered magnetic rings and bonded magnetic rings. Are there other types besides these two? That's the question we'll answer today.

There are also injection-molded magnetic rings, with typical examples being injection-molded ferrite magnetic rings and injection-molded neodymium magnetic rings.

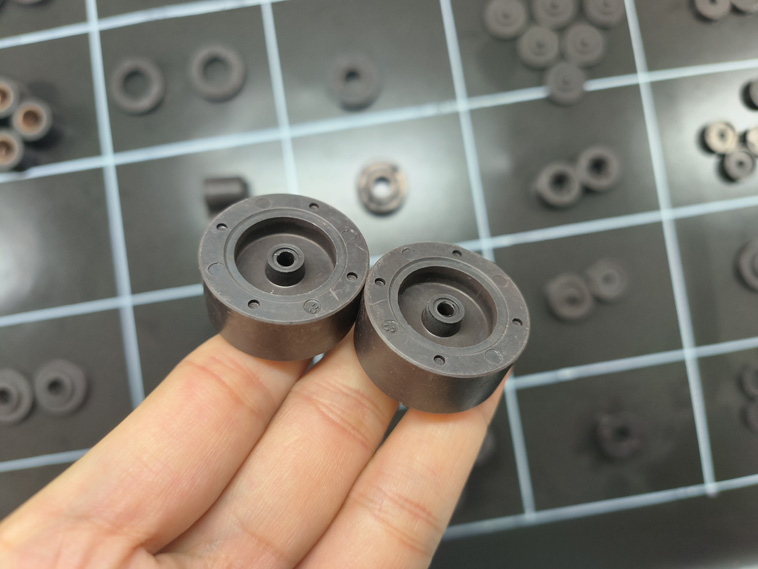

The image below shows the appearance of an injection-molded ferrite rotor ring magnet.

These three types of magnetic rings exhibit differences in magnetic properties, structural strength, cost, and suitable applications. For instance, Sintered magnetic rings typically refer to sintered neodymium iron boron rings or sintered ferrite rings. These rings are produced through powder orientation, pressing, and high-temperature sintering, resulting in high magnetic energy product and strong magnetic field intensity. They are suitable for motors and actuators requiring high output torque or magnetic field strength. However, their materials exhibit greater brittleness, necessitating extra care during processing and assembly, and their overall cost is relatively higher. Bonded magnetic rings primarily use neodymium iron boron magnetic powder as raw material. Their magnetic properties fall between sintered and injection-molded neodymium iron boron rings. They are easy to process into thin-walled structures and are widely used in electric tools, consumer electronics, home appliances, and other fields. Injection-molded magnetic rings represent a rapidly growing category in recent years. Typically formed by mixing magnetic powder with engineering plastics through injection molding, their advantages include high structural strength, the ability to be molded as a single unit with plastic components, and excellent dimensional stability. They are particularly suited for complex structures and high-consistency batch production, finding widespread application in motors, sensors, encoders, position detection, and other fields.

Additionally, magnetic rings can be further categorized by material, including rubber magnetic rings, samarium-cobalt rings, ferrite-cobalt rings, and aluminum-nickel-cobalt rings. Selection should comprehensively consider magnetic performance requirements, operating environment, cost, and assembly methods.

This concludes our introduction to the topic. Should your company require quotes, customization, or have any other inquiries regarding magnetic rings, please feel free to contact us.

More introductions to magnetic rings;

How to calculate the pole pitch of a multipole magnetic ring?

Comparison of multipole magnetic rings and arc magnet combined rotor

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier