In various types of motors, fans, pumps, and smart devices, there is an invisible but crucial component that determines whether the equipment can operate efficiently and smoothly. It is the magnetic rotor. So, what is a magnetic rotor? What are the main structural types and magnetic steel types? Continue reading below.

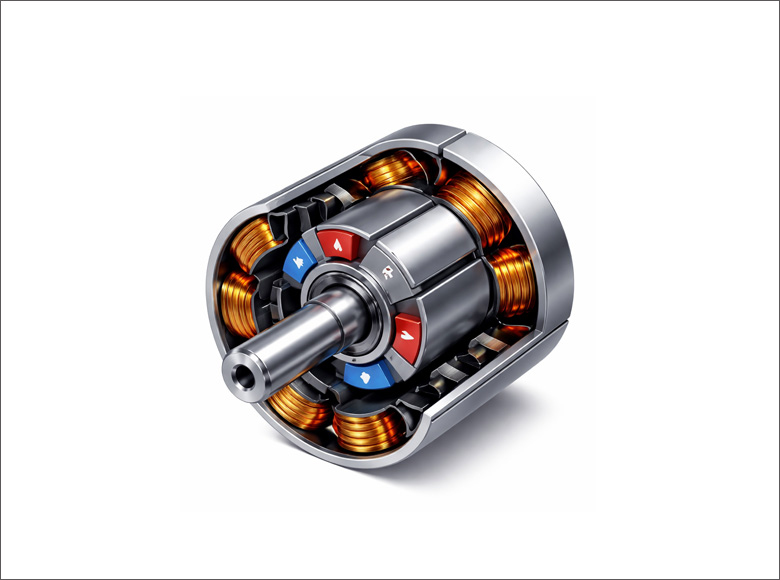

Magnetic rotor refers to a key component that integrates permanent magnets into the rotor structure, generates electromagnetic effects with the stator winding through its own magnetic field, and achieves the conversion of electrical and mechanical energy. It is one of the core components of permanent magnet motors, brushless DC motors, and various magnetic sensing devices.

Magnetic rotors can be divided into two categories based on the relative position of the magnet in the motor: magnetic inner rotors and magnetic outer rotors. The magnetic inner rotor operates internally relative to the stator. Magnetic steel is bonded to the outer wall of the iron sleeve and rotates at the center of the stator and the entire motor. The biggest advantage of the internal rotor structure is its ability to dissipate heat. The magnetic outer rotor works externally relative to the stator. The magnetic steel is bonded to the inner wall of the iron sleeve and rotates around the periphery of the stator. The biggest advantage of the outer rotor structure is that it can significantly reduce the cogging torque.

Magnetic rotor for electric motor

Whether for inner or outer rotors, common magnet configurations for magnetic rotors include sintered neodymium iron boron magnets (magnetic tiles/rings), sintered ferrite magnets (magnetic tiles/rings), as well as bonded and injection-molded magnets.

The above provides an overview of magnetic rotors. Injection-molded magnetic rotors exhibit slightly lower magnetic properties but offer superior toughness, vibration resistance, and impact resistance. Sintered neodymium-iron-boron magnetic rotors deliver strong magnetic force, making them suitable for high-power-density motors. The selection of magnet type requires comprehensive consideration.

Related magnetic rotor magnets;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier