Magnetic rotor assembly is a kind of magnetic assembly that combines permanent magnets with mechanical motion elements, utilizing the interaction between magnetic field and magnetic field to realize contactless power transmission and motion control, mainly used in the field of electric motors, the following is the introduction about its components, advantages and applications.

Construction of magnetic rotor assembly;

Generally consists of 1 or more magnetic permanent magnets and iron core or steel shaft, the permanent magnet material can be ferrite, neodymium iron boron, the rotor itself is rotatable.

Principle of operation of magnetic rotor assembly;

In a motor, the role of the magnetic rotor assembly is to convert electrical energy into mechanical energy. When current passes through the stator coils of the motor, the resulting magnetic field interacts with the magnetic field on the rotor, resulting in rotational motion of the rotor. This rotational motion is transferred to the mechanical device, which drives the associated work.

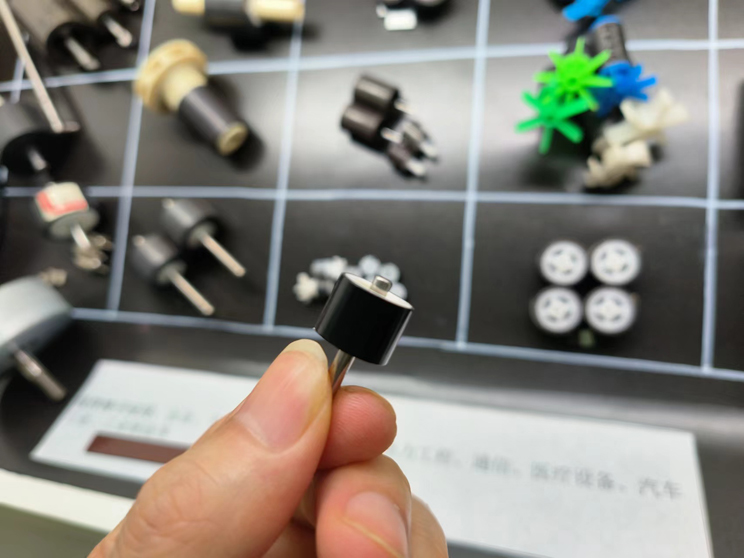

The figure below shows an injection molded ferrite magnetic rotor assembly

What are the advantages of magnetic rotor assemblies?

Magnetic rotor assemblies offer a number of unique advantages over traditional mechanical drives, such as:

No physical contact is required, resulting in no wear and tear, low noise levels, and long service life.

Can operate in a completely sealed environment, making them suitable for harsh operating conditions.

Fast response time and easy to realize precise speed/position control.

Compact and lightweight, which facilitates integration and saves space.

No lubrication required, low maintenance costs.

Magnetic rotor assemblies can be designed and customized according to different application requirements. Different types and shapes of magnetic materials can be used, as well as different pole arrangements to achieve flexible adjustment and optimization of motor and generator performance.

Application of Magnetic Rotor Assembly;

Magnetic rotor assemblies are widely used in various types of motors and generators, including AC motors, DC motors, synchronous motors, asynchronous motors, etc., and they play an important role in industrial production, transportation, household appliances and other fields.

Above is some introduction about magnetic rotor assembly, our company can provide all kinds of rotor or customized magnetic assembly for the majority of motor customers, welcome your inquiry.

Related Products Column;

Content that may be of interest to you;

Motor arc rotor magnets is too strong how to assemble more safe

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier