During the precision machining of strong neodymium magnets, a series of rigorous testing processes are usually required to ensure product quality, performance and reliability, and the following are the common testing processes involved in each type of magnet.

1、Raw material testing. The company strictly control the source of the magnet blank material to ensure that it meets the specified chemical composition and physical property standards, many magnets quality problems are here.

2、Precision machining before testing. Measure the key dimensions of the product to ensure compliance with the design requirements. Check the shape and appearance of the product to ensure that there is no deformation or damage.

3、Magnetic performance test. Measure the magnetic field strength of the product using magnetic field testing equipment to ensure that it meets the specified magnetic performance requirements. Analyze the hysteresis loop of the product to assess the stability and linearity of the magnetic properties.

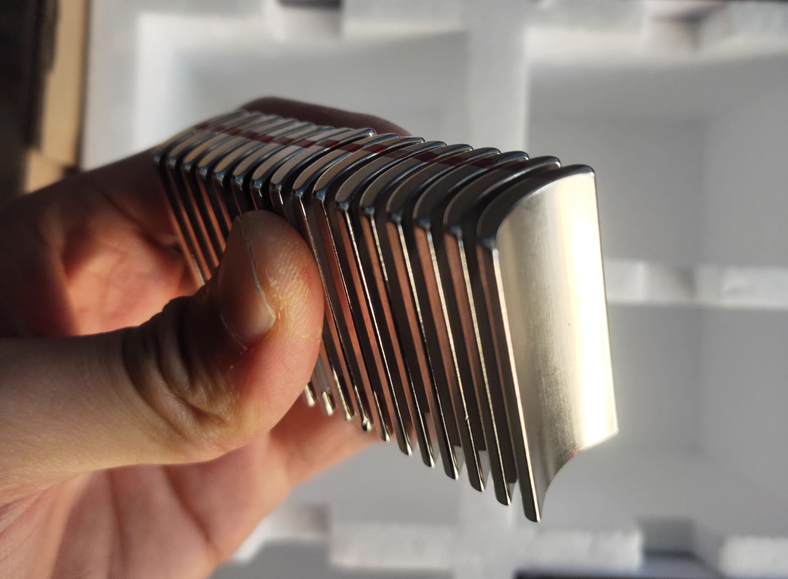

The picture shows neodymium segmented magnets recently shipped to a customer in the United States.

4、Dimensional testing. Ensure that the individual dimensions and tolerances of the magnets meet the customer's requirements.

5、Coating Inspection. If there is a coating on the surface of the magnet, carry out the quality inspection of the coating, including the uniformity, adhesion and corrosion resistance of the coating.

6、Pre-packaging inspection. Ensure that the product size and quantity meet the order requirements.

Through the above testing process, we can effectively ensure the quality and performance of strong magnetic NdFeB precision machining products to meet customer needs, if you need a quote, processing rare earth neodymium magnets, you can contact us through direct phone or online communication.

More introduction to magnet processing;

Why ring neodymium magnets need to process countersunk hole shape?

Different shapes of samarium cobalt magnet processing method

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier