In the previous issue of the article, mainly introduced the processing of sintered NdFeB, today this article is mainly to introduce you to the different shapes of samarium cobalt (SmCo) magnets processing methods.

1、Samarium cobalt magnets cylindrical set of holes processing

You can use drilling (drilling machine), reaming, laser processing and other ways of cylindrical samarium cobalt magnets processing holes, drilling machine is more common, suitable for general size of the hole. Reaming can be used to get more precise and flat set of holes, which is suitable for the requirement of higher precision and surface quality. Laser processing can be used for very precise set of holes making, especially for complex shapes.

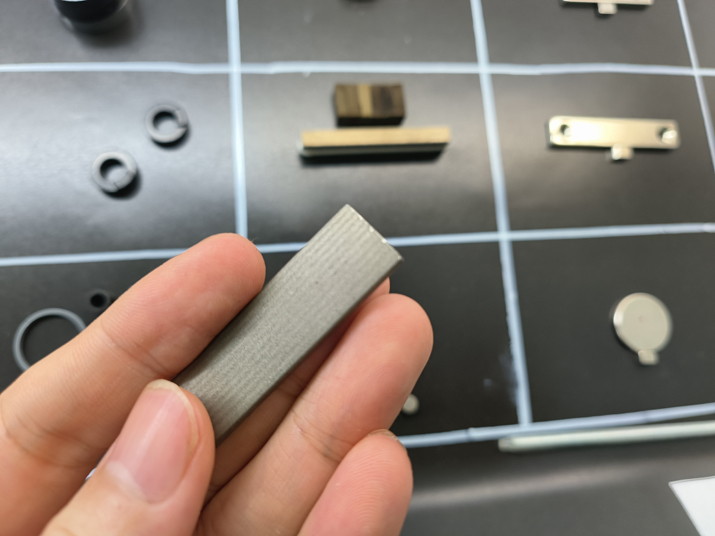

2、Samarium cobalt magnet processing for square or rectangular shape

Using cutting tools, such as shears, punches, etc., the original material can be cut into the required shape. Grinding is a method used to improve the dimensional accuracy and surface quality of square magnets, and a flatter and more precise surface can be obtained through grinding.

3、Radial thin-walled circular samarium cobalt processing

Radial thin-walled circular samarium cobalt is a common magnetic material, usually used in the manufacture of motors, sensors and sound equipment and other fields. In the processing of thin-walled center hole, it is easy to internal crack, it is more difficult to process, some magnet manufacturers therefore specialize in the production of a circular sleeve, with this sleeve to cover the product to be processed, and then put into the fixture, with the set of holes in the hole machining method to process the center hole, so as to reduce the chances of damage to the product.

4、Processing of curved samarium cobalt magnets

Use machining process, such as milling, turning, wire cutting or laser cutting, etc., to process the block material into the required arc shape. Can also use semi-automatic horizontal axis surface grinder direct grinding to replace the wire cutting process, the use of specially made movable fixture and customized molding wheel, direct grinding, efficiency, accuracy can be improved.

Arc-segmented samarium cobalt magnets

5、High precision samarium cobalt magnet processing

Nowadays, some high-tech products are coming out, which not only require high precision of magnets, but also have certain requirements on concentricity, perpendicularity and other shape and position tolerances. The use of cylindrical grinding machine through the mandrel grinding outer diameter or steel wire reference grinding outer diameter to meet the requirements of concentricity, as well as square, cylindrical products, verticality, the use of special fixtures, flat grinding processing to meet the requirements of high-precision applications.

6、Samarium cobalt processing for special shape

According to the design requirements of special shape, cut and grind the SmCo magnet to achieve the required shape and size.

The above introduces some common processing methods of samarium cobalt magnet, if you need quotation, processing samples, you can contact us through online customer service on the right side of the web page.

Other samarium cobalt magnet knowledge science;

Difference between SmCo5 and Sm2Co17 magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier