Passivation of magnet surfaces is used to increase the corrosion resistance of magnets and to improve their surface stability. Passivation can be achieved by different methods, which include chemical treatment, electrochemical treatment and other methods.

Chemical treatment: Chemical passivation prevents corrosion by forming a layer of chemically stable compounds or oxides on the surface of the magnet. This can be achieved by pickling, phosphating, chromate treatment, etc. to form a protective oxide or compound layer.

Electrochemical treatment: Electrochemical passivation utilizes electrochemical principles to form a protective oxide or compound layer on the magnet surface. This method usually includes techniques such as anodic oxidation, anodic protection and electroplating, whereby the current and voltage are controlled to form a layer with corrosion resistance.

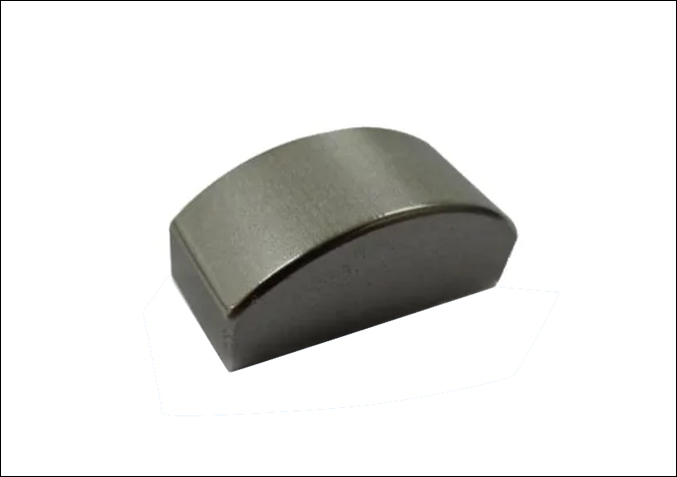

Bread-type neodymium magnets with passivated surface treatment

NdFeB passivation process flow;

Cleaning: First, the newly prepared or processed NdFeB magnets are cleaned to remove grease, dust and impurities from the surface. Commonly used cleaning methods include solvent cleaning, alkaline cleaning or ultrasonic cleaning.

Descaling: If oxides or rust are present on the surface, descaling is required. An acidic solution or other chemical method is usually used to remove the oxidized layer and make the surface clean and smooth.

Passivation: One of the common methods of passivating NdFeB is chemical passivation, which improves corrosion resistance by forming a protective oxide or compound layer on the surface. This can be accomplished using acidic solutions or other specific chemical treatment agents.

Cleaning and neutralizing: After treatment, magnets require thorough cleaning to remove any residual treatment agent. Subsequent neutralization may be required to neutralize any acids and bases that may remain on the surface.

Drying: Once the treatment is complete, the magnets need to be dried to ensure that the surface is completely dry to prevent new corrosion from forming.

Inspection and Packaging: Finally, the passivated NdFeB magnets are inspected to ensure the quality and integrity of the passivation layer. They are then packaged to prevent re-exposure to corrosive environments.

Advantages of chemical passivation treatment on the surface of NdFeB permanent magnets:

1, Thin film, passivated NdFeB permanent magnets are glossy metal color, film corrosion resistance is excellent;

2, Salt spray test for 2 hours up to nine levels, double 85 (85 ℃, R.H. 85%) up to 5 hours without rust spots;

3, The film layer has excellent electrical conductivity, surface adhesion of more than 25MPa, and its spraying after the hundred frame test up to level 0;

Related neodymium magnet coating introduction;

Neodymium Magnet Surface Phosphate Coated Treatment Introductio

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier