What is alnico magnet?

Aluminum nickel cobalt permanent magnets is an alloy composed of metal aluminum, nickel, cobalt, iron and other trace metal elements. The composition of its metal components is different, and the magnetic properties are different, so the use is also different.

The alnico magnet was invented in Japan in the early 1930s, the specific time was about 1931. The original synthesis did not contain cobalt and was called alni. With the discovery of cobalt's enhanced magnetism, the composition of cobalt changed several times between 1935 and 1974, culminating in alnico 9. The introduction of alnico means that expensive electromagnets can be replaced by permanent magnets for devices such as motors, generators, and speakers. It is worth mentioning that alnico magnets were used in military electronics applications during World War II. After the 1860s, with the emergence of ferrite magnets and rare earth permanent magnets, the use of alnico gradually decreased.

Production process of aluminium nickel cobalt magnet;

Casted: The casting process can be processed into different sizes and shapes. In permanent magnet materials, cast alnico permanent magnet has the lowest reversible temperature coefficient, and the operating temperature can be as high as 500℃ or more.

Sintered: Compared with the casting process, the sintered products are limited to small sizes, and the blank products produced by them have small dimensional tolerances and good casting machinability.

What shapes can Alnico magnets be machined into?

The shapes that can be produced are round, cylinder, ring, rectangular, flat, arc/segment, horseshoe and so on.

What are the advantages of Alnico permanent magnet?

High temperature resistance: AlNiCo magnets have excellent high temperature resistance and can maintain good magnetic properties in high-temperature environments. Usually, they can operate in the temperature range of 450 ° C to 550 ° C, which makes them widely used in high-temperature applications.

Corrosion resistance: AlNiCo magnets have relatively high resistance to oxidation and corrosion, giving them advantages in some special environments. In contrast, other permanent magnet materials such as neodymium iron boron magnets are more sensitive to corrosion.

What are the disadvantages?

Weak magnetic force: Although AlNiCo magnet has relatively high Coercivity and Coercivity coefficient, its magnetic force is relatively weak compared with other permanent magnetic materials (such as neodymium iron boron magnet). This may limit the use in applications that require higher magnetic field strength.

Expensive raw material costs: The raw material components in aluminum nickel cobalt magnets include rare metals such as aluminum, nickel, and cobalt, which are relatively expensive due to their high prices. Compared with other permanent magnet materials, such as ferrite magnets, AlNiCo magnets have higher manufacturing costs.

What is the density of Alnico?

The density of Alnico magnets is about 7.0-7.3g/cm3.

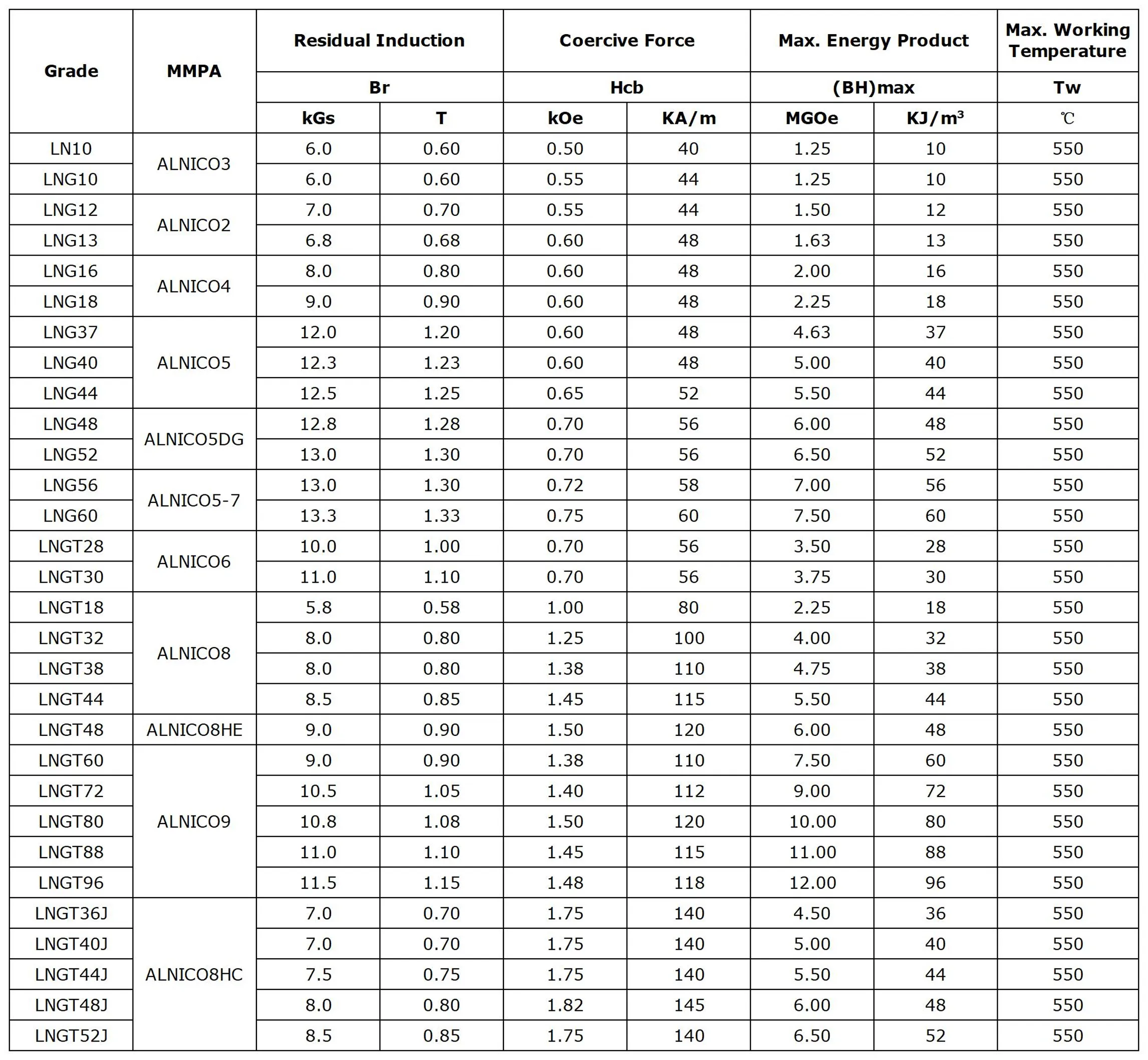

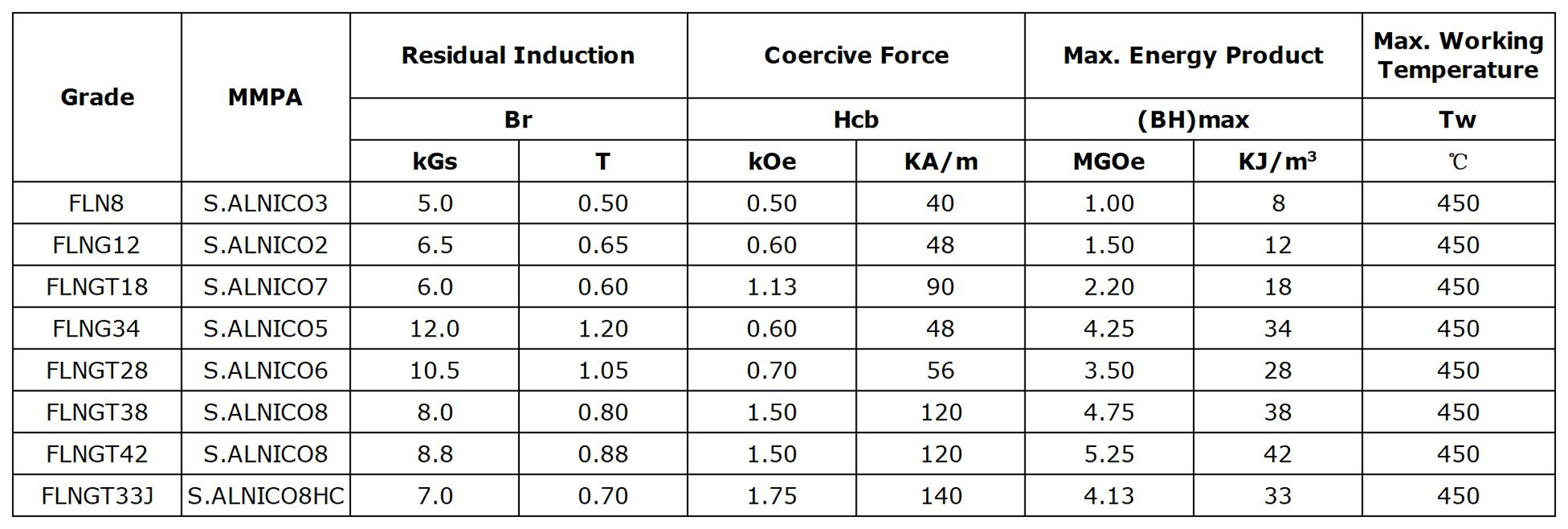

Magnetic properties parameters of aluminum nickel cobalt magnets;

The Performance data of Sintered alnico:

Magnetic properties of cast aluminum nickel cobalt:

The application of alnico:

It is widely used in Permanent magnet motor (gradually replaced), aerospace military magnetic voltage ammeter, electronic energy meter, multimeter, flow meter, all kinds of magnetic sensors, temperature and pressure controllers, mobile phone buzzer, hearing aid, receiver, micro speaker, automotive ignition starter, instrumentation, magnetoelectric switch, communication equipment, etc.

Thank you for you reading! If you have any other question, please contact us for quotation!

Here's an article you might want to read;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier