Alnico magnets and neodymium-iron-boron (Ndfeb) magnets are two common permanent magnet materials, they are different in many ways, today's permanent magnet supplier Courage Magnets Xiao Fu to introduce you.

1、Difference in appearance

NdFeB strong magnets are easy to oxidize due to the metal neodymium, and need surface plating. And AlNiCo has better corrosion resistance, usually not surface treatment.

Alnico block magnet appearance picture

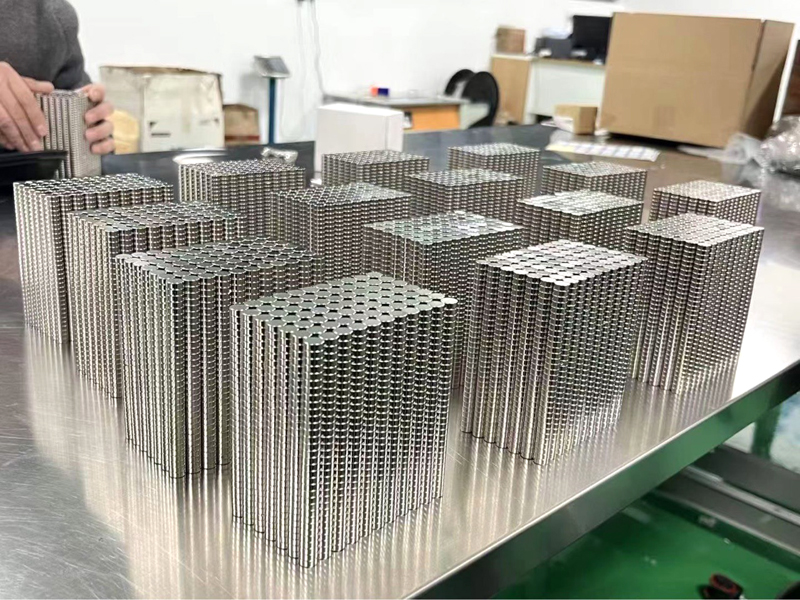

Rare earth neodymium round magnet appearance picture

2、Difference between Alnico and NdFeB in material

The fracture of the two products is not the same, NdFeB is very fine small crystals, while AlNiCo section is much rougher and the crystal particles are bigger.

3、Difference in working temperature

NdFeB ordinary can withstand 80 ℃. Alnico magnets in 300---500 ° (Alnico magnets in more than 600 ° C temperature demagnetization, so we generally say that the working temperature of Alnico magnets less than or equal to 550 ° C).

4、Alnico and neodymium magnets in magnetic strength difference

Alnico is a high-temperature resistant magnet, but the magnetic properties are very weak, the magnet is the more high-temperature resistant, the magnetic force is relatively weaker, the magnetic force is inversely proportional to the temperature resistance, neodymium magnets are much stronger than Alnico.

5、Alnico vs NdFeB Density

NdFeB magnets have a density of 7.5-7.6g/cm3 and Alnico magnets have a density of 7.0-7.4g/cm3.

6、The price difference between these two

Aluminum nickel cobalt because of its strategic resources cobalt and nickel, so the price is expensive, few people use, many customers choose neodymium iron boron instead.

7、Differences in application

Alnico magnets are commonly used in the manufacture of sensors, measuring instruments, electric motors, generators, and other applications that require high temperatures and high magnetic field stability.

NdFeB magnets are commonly used in the manufacture of electric motors, wind turbines, magnetic couplers, magnetic resonance imaging (MRI) equipment, and other applications that require strong magnetic force.

Above is the 7 points about the difference between neodymium magnet and aluminum-nickel-cobalt introduced for you by Courage Permanent Magnet Manufacturer, need to buy permanent magnets please send us an inquiry.

More Alnico knowledge;

Alnico vs ferrite magnets in speakers

Alnico 5 vs Alnico 8 [Strength Component Application]

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier