Neodymium magnets have different types of magnet coatings, the main coatings are nickel-copper-nickel, zinc, epoxy, gold, rubber and so on. Each type of coating has its own unique characteristics, corrosion resistance, collision resistance and price are not the same.Today Daisy will introduce you to rubber coating magnets. I hope it will be helpful to you.

First, what is rubber coated neodymium magnet?

Rubber coated neodymium magnets, also known as coated strong magnets. It is common for magnets to be coated with black isoprene rubber. Combining the advantages of neodymium iron boron (NdFeB) magnets and rubber materials. They are among the most widely used magnets in various industries. Rubber-coated magnets are known to be very durable and provide excellent friction and protection.

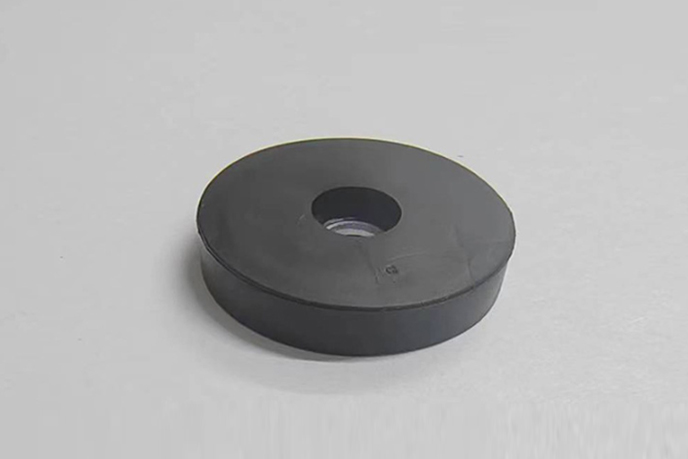

Rubber-coated neodymium magnet picture, If you don't look closely, you might mistake it for a ferrite ring magnet.

Second, the type of rubber coated magnet:

They are ideal for outdoor and indoor use. Due to their high anti-slip properties, this type of magnet is commonly used for fixing and mounting applications. Rubber-coated magnets are available in different designs, such as disc, ring, external thread, internal thread, countersunk hole and screw hole.

Third, the advantages of rubber coated neodymium magnets

1. Strong corrosion resistance

The rubber material itself is resistant to corrosion, and usually the rubber coating will be much thicker than other types of coating for the magnet. This also makes the coating suitable for use in wet environments, thus acting as a protection for the powerful magnets inside.

2.High skid resistance rubber has high friction.

The ordinary coating is easy to slip when adsorbed on a smooth surface, but the rubber coating will not, because of its material problems, it will have high friction.

3. Good temperature characteristics

Rubber-coated magnets can work normally at a high temperature of 80℃ and a low temperature of minus 40 ℃.

4. Wide variety of colors

The most common is black, but it can also be adjusted to blue, yellow, green, and other colors according to needs.

Finally, the uses/application of rubber coating magnets

Rubber coating magnets are coated with high quality rubber to ensure safe contact. It can effectively prevent the surface from coming into direct contact with sharp hard objects, thus minimizing scratches. Neodymium rubberized magnets are also suitable for other stationary applications that require protection from contact with steel surfaces.

Rubber coating magnets can be applied to disk, block, ring, and even plate magnets. Ideal for aquariums, Marine environments, construction sites, outdoor applications, wind energy, automotive or other metal surfaces, etc. Rubber magnets were invented for maximum softness and scratch resistance. It has excellent chemical stability, but its use in high temperature, low temperature and corrosive environments may shorten its service life.

In summary, the rubber coating is suitable for use in harsh environments, but the general size is not conventional, and it is best to communicate with the magnet factory in advance.

China Courage Magnet Manufacturer

China Courage Magnet Manufacturer

WeChat

Scan the QR Code with WeChat