Injection molded magnet is composed of nylon and magnetic powder,and it is produced by injection molded by special injection molded machine. Compared with other methods of making permanent magnets, injection molding has unique and irreplaceable advantages. The material including Ndfeb, ferrite and samarium cobalt.

Why use the injection molded magnet? What unique advantages does injection molded magnet have?

Injection molded can made in special shape magnet. Moreover, the injection molding process can adopt the methods of "embedded molding", "multi-step molding" and "multi-work-piece molding" to combine the magnet with other parts, thus saving the cost of secondary processing and assembly.

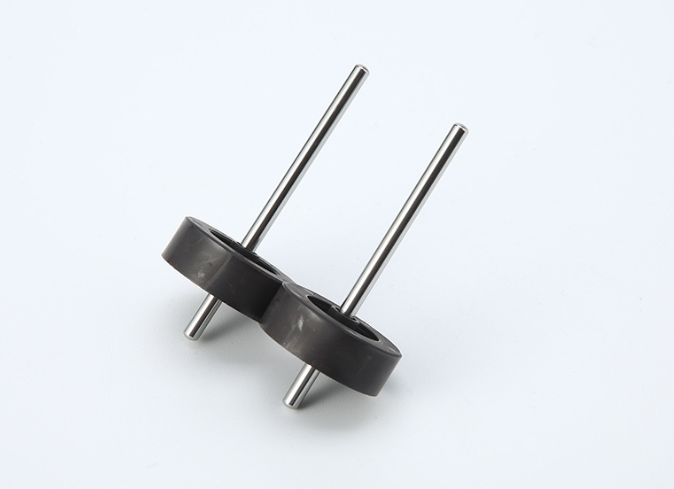

Appearance of injection molded ferrite rotor magnets

Injection molding technology can produce both isotropic barriers and anisotropic magnets. The anisotropic magnet needs an external orientation magnetic field when forming, so that the magnetic powder has a certain direction in the molten state of the polymer, namely the orientation, and can realize multipole magnetization. The injection molding process makes the product have better consistency in size and performance. During the molding process, the mold cavity is completely filled with the material at the highest concentration under the strong injection pressure, in addition the material contains the thermoplastic binder, which makes the magnet obtain good performance and accuracy in physical and mechanical.

Performance: Due to the high content of polymer binder in injection molded magnets, the magnets themselves have strong corrosion resistance, and usually do not need to be protected by surface coating.

Dimensional accuracy: Because the injection molded product is consistent with the injection mold cavity in size, the accuracy of product size can be controlled relatively high. In addition, the shrinkage of the binder in the material will cause changes in the size of the product when it become cooled. The degree of shrinkage depends on the thickness and shape of the product. The typical dimensional tolerance is ±0.05mm.

PS: injection molding magnetic has another feature: can make durable consumer product, 20~150 degrees do not demagnetize!

The appilication of injection molded magnets:

Injection molded magnets are mainly used in automation equipment, brushless DC motor rotor, variable frequency fan motor rotor, variable frequency air conditioning motor rotor, brushless DC refrigerator damper motor rotor, energy-saving range hood, automobile oil tank magnetic ring, instrumentation, lamps, printers and copiers magnetic roller, buffer cylinder, water pump motor, water heater accessories, energy-saving induction cooker, swimming pool equipment pipeline accessories, motorcycles Car, camera, clock, sound, all kinds of motor induction dew parts, household appliances, household floor electric fans, ceiling fans, exhaust fans, air coolers, air fans, office automation, transmission, all kinds of toys, magnetic medical care equipment and various fields of daily life and so on.

If you want to obtain further content, such as injection molded magnet (Ferrite or neodymium) price, specifications, performance and other more information, you are welcome to contact us at any time, we welcome all customers to consult and negotiate!

Related injection molding magnetic products;

Injection molded neodymium magnets

Injection molded ferrite magnets

Editor's Recommended Article;

Injection molding magnets how to increase the surface magnetism

Difference between bonded NdFeB and injection molded ferrite magnet

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier