Magnet drilling is a very simple thing for magnet manufacturers to do, you can do the drilling job for various shapes of magnets, the number of holes can be 1 hole, 2 holes, or more than one hole, the position of the holes can be centered, or off to the left, off to the right, as well as where you need it to be.

For individuals, drilling holes for magnets is challenging. The commonly used magnet materials are mainly NdFeB, Ferrite or Alnico, which are hard and brittle, and can easily break during the process.

If you need to drill a hole in a magnet, here are a few considerations:

1. Use the Right Tools

Use a drill press if possible, as it provides more stability and precision.

Choose a drill bit designed for the specific material of the magnet (e.g., cobalt or carbide for neodymium magnets).

2. Slow Speed and Coolant

Drill at a slow speed to prevent overheating, which could demagnetize the material.

Use a coolant to keep the temperature down.

3. Safety Precautions

Wear safety glasses and protective gear.

Secure the magnet properly to prevent movement during drilling.

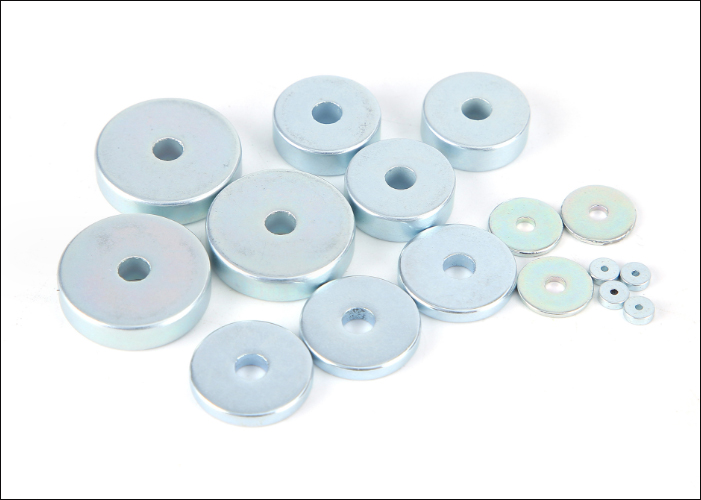

The most common drilling magnets types - neodymium ring magnets

4. Demagnetization Risk

Note that drilling can alter the magnetic field and may partially demagnetize the magnet in the vicinity of the hole.

5. Post-Drilling Magnetization

Some manufacturers offer remagnetization services if the magnetic properties are significantly affected.

6. Consider Alternatives

If you need a specific shape or feature in a magnet, consider purchasing magnets with pre-made holes or other configurations to avoid drilling.

This is all about whether you can machine holes in magnets, I don't recommend doing this yourself, if you do want to try it, remember to be safe.

Introduction to related perforated magnet machining;

Can rare earth neodymium magnets be drilled hole or cut?

Why ring neodymium magnets need to process countersunk hole shape?

Perforated magnet case;

Rectangular block magnet with 3 mounting holes manufacturer

Ring neo magnet with through holes on the side

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier