BNP is the prefix for bonding neodymium iron boron materials, where B represents bonding, N represents neodymium iron boron, P represents magnetic powder, and BNP-12 is one of the performance grades. The following is an introduction to its parameters and applications that you would like to know more about.

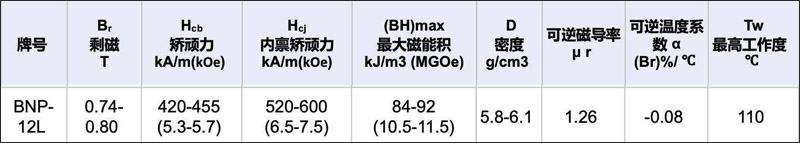

The image below shows the magnetic parameter range for bonded ndfeb BNP-12L magnets.

The above represents the typical parameter range for pressed/bonded BNP-12 series magnets. Compared to sintered neodymium iron boron magnets, the magnetic properties of bonded materials are only 50-60% of the latter. Different manufacturers (including sub-grades such as BNP-12, BNP-12L, and BNP-12D) may exhibit slight variations in Br, coercivity, BHmax, operating temperature, and pole alignment consistency.

BNP-12 bonded neodymium iron boron magnetic rings find extensive application in miniature brushless DC motors. Such motors are commonly employed in power tools (e.g., electric screwdrivers, angle grinders), personal care products (electric toothbrushes, electric shavers, beauty devices), medical equipment (surgical instruments, ventilator fans), and office equipment (printer feed motors, scanner drives). The magnetic ring is directly fitted onto the rotor shaft, employing 4-pole, 6-pole, or 8-pole radial magnetisation to form multiple pairs of alternately distributed N-S magnetic poles.

Rotary encoders represent another significant application for BNP-12 magnetic rings. Within incremental encoders, the multi-pole magnetised ring is mounted on the rotating shaft, surrounded by Hall sensors. These sensors detect changes in the magnetic poles to generate pulse signals, enabling angle and speed measurement. Typical configurations employ 10-, 12-, or 16-pole rings paired with 2-3 sensors to generate orthogonal encoding outputs.

In applications requiring non-contact power transmission, the BNP-12 magnetic ring serves as the core component of magnetic couplings. Two multipole rings are fixed to the drive and driven shafts respectively, transmitting torque through magnetic field coupling without mechanical contact.

With the increasing electrification of modern vehicles, the BNP-12 magnetic ring plays a role in multiple automotive subsystems. Common applications include electronic throttle control, electronic parking brake (EPB) systems, tailgate motors, seat adjustment motors, rear-view mirror adjustment motors, sunroof motors, and water pump motors.

Should you currently possess specific dimensions for the BNP12 magnetic ring and the number of magnetic poles, please contact our customer service team for a quotation or to locate existing or similar samples. We offer custom moulding services.

Selection of bonded magnet dimensions;

Bonded Neo Ring & Arc Shaped Magnets

Many people remain interested;

Frequently Asked Questions about Bonded Neodymium Magnets

How are bonded neodymium magnetic rings magnetized?

Bonded NdFeB Physical Characteristics and Properties DataSheet

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier