Ndfeb and Smco magnets are rare earth permanent magnets, what are the differences between these two magnets? Today, the magnet supplier courage magnet will introduce to you the difference between NdFeb and SmCo in composition, appearance, magnetic strength, temperature resistance, price and application.

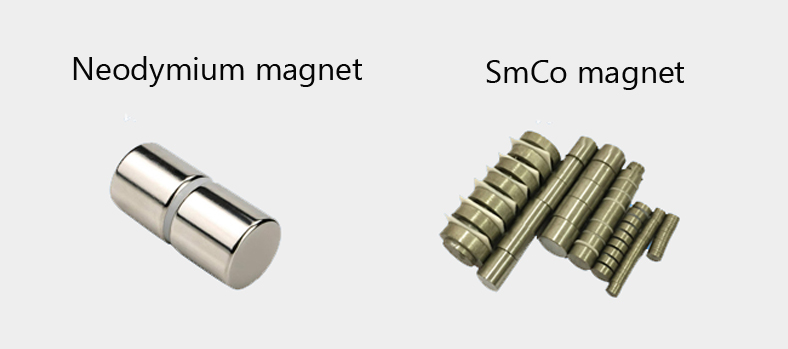

The following is a comparison of the appearance of neodymium magnet and samarium cobalt magnets;

Ndfeb magnet products are generally after electroplating treatment, the appearance is bright, according to the coating is different, there are a variety of colors.

The samarium cobalt magnet does not need to do surface plating, so the finished appearance is the same as the blank.

Difference between samarium cobalt and Ndfeb magnets in composition and composition;

Samarium cobalt magnet: It is composed of samarium (Sm), cobalt (Co) and other metal rare earth materials by matching, melting into alloy, after grinding, pressing, sintering made of a magnetic material, currently mainly SmCo5 and Sm2Co17 two components.

Neodymium magnets: The main raw materials are rare earth metals neodymium, praseodymium, holmium, common metal iron, aluminum, ferroboron alloy and other rare earth raw materials, its chemical formula is Nd2Fe14B. Neodymium magnets can be divided into bonded neodymium and sintered neodymium. Bonding is actually injection molding, while sintering is vacuum molding by high temperature heating.

Performance strength of Smco VS NdFeb;

Relatively speaking, the overall performance of samarium cobalt magnets is lower than that of neodymium magnets.

Neodymium magnets are by far the strongest permanent magnets at room temperature, second only to holmium magnets at absolute zero, but by far the strongest permanent magnets at room temperature. Its BHmax value is 5-12 times that of a ferrite magnet and 3-10 times that of an aluminum-nickel-cobalt magnet. Its coercive force is equivalent to 5-10 times that of ferrite magnets, 5-15 times that of aluminum nickel cobalt magnets, and its potential magnetic properties are extremely high, and it can absorb heavy objects equivalent to 640 times its own weight.

Samarium cobalt magnets are the second strongest magnetic magnets today, with a high maximum magnetic energy product (BHmax), high coercivity, brittle, easy to crack. The maximum magnetic energy product of samarium-cobalt magnets ranges from 9 MGOe to 31 MGOe. Magnetic coercivity (Hcb) ranges from 650-870 (KA/m) to 4-12(Koe).The remanence (Br) range is 8-12(KGs),0.8-1.2(T). The remanent reversible temperature coefficient (Br) ranges from -0.04--- -0.01

Temperature resistance of Smco VS Neodymium magnets;

Conventional NdFeB magnets can work well at room temperature, but when the temperature exceeds a certain range, the magnetic properties will sharply decrease until they lose their magnetism. Specifically, the operating temperature range of NdFeB magnets is typically between 80 ° C and 220 ° C.

SmCo: In contrast, SmCo has better temperature resistance, and the working temperature range of SmCo magnets is usually between 250 ° C and 350 ° C, depending on the specific alloy formula.

Comparison of samarium cobalt and neodymium magnets in corrosion resistance;

Samarium cobalt magnets have good corrosion resistance and can be used in some poor environments, such as wet or corrosive gases.

Neodymium magnets are more fragile, easy to oxidation and corrosion, and need to take protective measures, such as electroplating.

Difference between samarium cobalt and NdFeb permanent magnet in surface treatment;

Neodymium magnet is easy to corrode and oxidize because of the many iron elements in the composition, so it is generally necessary to deposit, and the coating is mainly galvanized, nickel plated, gold plated, silver plated, chromium plated, epoxy plated and so on.

Samarium cobalt magnets are not easy to corrode, so there is no need for coating treatment.

Samarium cobalt and NdFeb which price is more expensive?

Samarium cobalt magnets and neodymium magnets of the same performance size, the price of neodymium iron boron is lower than samarium cobalt.

The content of iron in neodymium iron boron is higher, the content of rare earth elements is less, and the price of iron is cheap, so the price of neodymium is cheap. The content of rare earth elements samarium and cobalt in samarium cobalt magnets accounts for about 70%, so the price is slightly higher.

Difference between smco and NdFeb in application;

Neodymium magnets is usually widely used in applications that require high magnetic performance, relatively low cost, and low temperature, such as motors, generators, electronic equipment, sound equipment, etc. Samarium cobalt is more suitable for applications in special environments such as high temperature and corrosion resistance, such as aerospace, national defense, and petroleum exploration. However, the specific application selection still depends on specific requirements, performance requirements, and cost considerations.

The above is a comparison of the differences between rare earth samarium cobalt and Neodymium magnet in many aspects. If you need to buy, or learn more, you can continue to pay attention to this website.

Content related articles recommended;

Main composition and proportion of rare earth neodymium magnet

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier