In aluminum-nickel-cobalt (AlNiCo) magnets, one often encounters different grades such as AlNiCo2, AlNiCo3, AlNiCo5, AlNiCo8, and AlNiCo9. Many people are puzzled by the numbers following these designations, unsure whether they indicate magnetic strength or represent specific material composition ratios. The following information is key.

In fact, the “2” in AlNiCo2 is not a performance grade number nor a direct ranking of magnetic strength, but rather a designation for a material grade. It is primarily used to distinguish aluminum-nickel-cobalt magnets with different formulations and magnetic characteristics.

The naming convention for aluminum-nickel-cobalt magnets is: Al–Ni–Co + material grade number. Thus, AlNiCo2 denotes an aluminum-nickel-cobalt magnet, where “2” represents the specific chemical composition ratio of this material. This corresponds to its magnetic performance range and typical characteristics. In other words, the number serves merely as a material series identifier and does not indicate any ranking of magnet quality or strength.

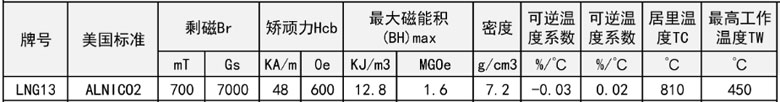

AlNiCo2 Magnetic Properties Data

Taking AlNiCo2 as an example, it typically has the following composition (approximate range): aluminum (Al) approximately 10–12%, nickel (Ni) approximately 15–20%, cobalt (Co) approximately 10–13%, iron (Fe) approximately 55%, and trace amounts of other elements such as copper and titanium.

Different numbers represent different proportions of AlNiCo content, which is why the number serves as a “material grade.”

Different grades of aluminum-nickel-cobalt exhibit distinct performance characteristics. Taking common grades as examples, AlNiCo5 boasts a magnetic energy product of approximately 32-40 kJ/m³, making it one of the grades with the most optimal comprehensive performance in this series. It is widely used in precision fields such as instrumentation and sensors. AlNiCo2, however, has a relatively lower magnetic energy product of about 11-14 kJ/m³, but it offers moderate coercivity and lower cost, making it suitable for applications with less stringent magnetic performance requirements. Higher grades like AlNiCo8 and AlNiCo9 exhibit greater coercivity and stronger resistance to demagnetization, yet their remanence is still inferior to that of AlNiCo5.

When selecting AlNiCo magnets, one should not rely solely on grade numbers but rather match appropriate performance parameters to actual application requirements. For stable operation in high-temperature environments, focus on Curie temperature and temperature coefficient. AlNiCo magnets can withstand temperatures of 450-550°C, an advantage unmatched by neodymium iron boron. When strong reverse demagnetizing fields exist in the magnetic circuit, grades with high coercivity should be selected. For applications like instrument pointers and speakers, residual magnetism and magnetic energy product are more critical. Additionally, factors such as cost budget, processing difficulty, and service life must be considered. Only through comprehensive evaluation can the optimal decision be made.

In conclusion, the "2" in AlNiCo2 represents the material grade number of aluminum nickel cobalt magnetic steel, indicating its specific chemical composition and magnetic combination, and is not directly related to the strength or numerical value of the magnetic force. Therefore, in terms of magnetic strength, AlNiCo9>AlNiCo8>AlNiCo5>AlNiCo2 is incorrect.

You might also be interested in:

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier