Magnets have a certain understanding of friends know that ferrite magnets are divided into wet-pressure process and dry-pressure manufacturing process, and to be magnetic ferrite magnets are used in wet-pressure, this is why? Today, the permanent magnet manufacturer Courage xiaofu to share this knowledge with you.

The main reasons for the better magnetic properties of wet press molded ferrite magnets are as follows:

1. Wet compression molding due to more moisture in the slurry, the grains can rotate freely in the molding process, facilitating grain orientation, and thus good magnetic properties, Br large Hcb high.

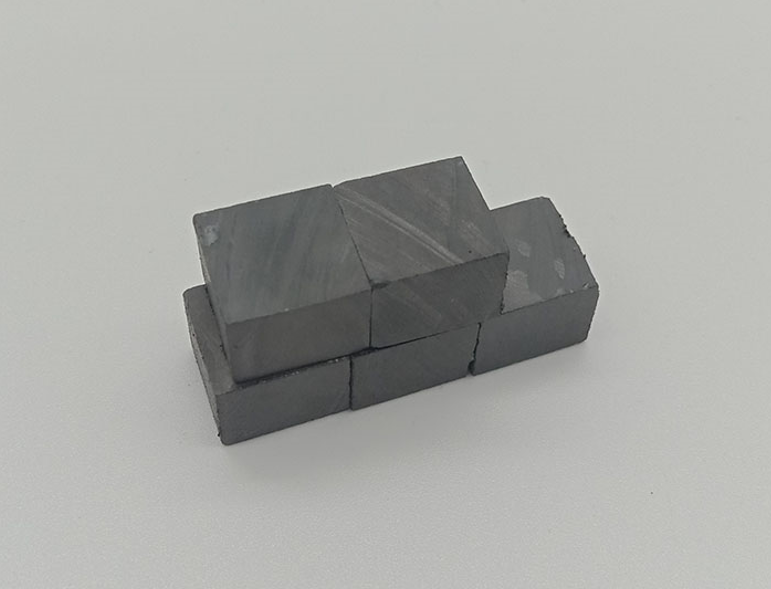

The accompanying picture shows ceramic square ferrite magnets

2. Wet compression molding allows for higher compaction densities at relatively low pressures, which means more magnetic powder can be compressed into the same volume. This helps to increase the magnetic moment of the magnet, thus increasing the magnetization strength.

3. The solvent in the wet compression molding process reduces the oxidation of the ferrite powder and helps to maintain the magnetic properties. In addition, wet compression molding provides better control over the particle size and distribution of the magnetic powder, which is also important for improving magnetic properties.

It should be specifically noted that wet press molding is not superior to dry press in all cases, and that dry press molding may still be the more appropriate choice for specific applications and requirements, depending on a combination of factors such as the composition of the material, the type of additives, and the sintering process.

Above is the introduction of why wet-press ferrite magnetism is better than dry-press ferrite magnetism, if you need ferrite permanent magnets quote, ask for samples welcome to contact Courage.

Related wet compression molding ferrite articles;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier