High coercivity magnets refer to permanent magnet materials with elevated coercivity (Hcj) that resist demagnetization under strong external magnetic fields, high temperatures, or complex operating conditions. Higher coercivity enhances resistance to demagnetization by opposing magnetic fields or elevated temperatures. These magnets are primarily used in high-speed, high-temperature, and strong opposing magnetic field environments. The following sections outline their material types, core advantages, and typical applications.

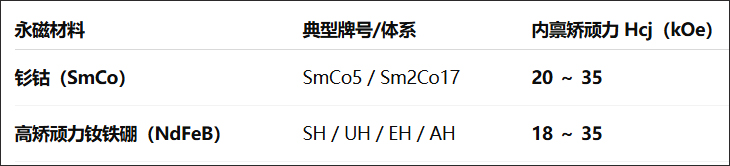

Common high coercivity magnet materials include samarium cobalt (SmCo) and high-temperature neodymium iron boron (NdFeB). Both share the characteristics of high intrinsic coercivity and strong resistance to demagnetization, maintaining stable magnetic properties under intense reverse magnetic fields, high temperatures, or complex operating conditions. They serve as core magnetic material choices for modern high-performance motors and high-reliability equipment.

Samarium-cobalt magnets typically exhibit an intrinsic coercivity ranging from 20 to 35 kOe, with a relatively flat temperature response. Their low coercivity temperature coefficient ensures exceptional thermal stability. Samarium cobalt's high Curie temperature and strong magnetic anisotropy energy enable it to maintain excellent resistance to demagnetization even in high-temperature environments ranging from 200 to 350°C, with minimal magnetic property degradation during long-term operation. Additionally, samarium-cobalt exhibits excellent corrosion resistance and reduced reliance on surface coatings, making it suitable for harsh environments and high-reliability applications. However, its higher material cost, greater brittleness, and challenging machinability limit its adoption in mass-produced, cost-sensitive products. It is predominantly used in aerospace, defense, and high-temperature specialty motors where extreme stability is paramount.

In contrast, high-temperature ndfeb magnets represent a high-performance system developed from conventional neodymium-iron-boron magnets. This is achieved through the addition of heavy rare earth elements or grain boundary diffusion processes, significantly enhancing the intrinsic coercivity. Common grades include SH, UH, EH, and AH. These magnets not only exhibit high coercivity ranging from 18 to 35 kOe at room temperature but also retain the inherent advantages of high remanence and high energy product characteristic of neodymium-iron-boron magnets. They are exceptionally well-suited for designs demanding stringent requirements for compact size, lightweight construction, and high power density. Although the coercivity of high-temperature neodymium-iron-boron decreases significantly with rising temperatures, selecting higher grades and incorporating a coercivity safety margin enables stable operation across 120–200°C. This makes them the mainstream solution for electric vehicle drive motors, high-speed motors, multi-pole magnetic rings, and high-speed rotors. Compared to samarium-cobalt magnets, high-temperature neodymium-iron-boron magnets offer superior overall performance and cost-effectiveness, but they demand stricter requirements for coating protection and thermal management.

Coercivity data of two types of high-coercivity magnets

The primary advantages of high coercivity magnets are strong resistance to demagnetization, excellent high-temperature stability, and superior reliability and longevity.

Why weren't ferrite magnets mentioned? Because ferrite's intrinsic coercivity Hcj isn't particularly high—it falls short of even standard neodymium iron boron magnets. So why are ferrites more temperature-resistant? This is due to their differing temperature stability. Ferrite's magnetic properties decrease slowly with rising temperatures, while neodymium iron boron decreases rapidly (approximately 2–3 times faster than ferrite). Consequently, in medium-to-high temperature environments, ferrite exhibits more “stable” magnetic performance changes, whereas standard neodymium iron boron magnets face a higher risk of thermal demagnetization.

In applications, high coercivity magnets are primarily used in brushless motors, permanent magnet synchronous motor rotors, new energy vehicle drive motors, high-speed motors, servo motors, magnetic encoders, aerospace, and military equipment.

That concludes the article. When selecting magnets, focus not only on the coercive force Hcj but also on the coercivity Hcj.

You might be interested in;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier