In permanent magnet synchronous motors (PMSM), the rotor structure significantly impacts the motor's efficiency, power density, and operational stability. The V-shaped magnet rotor, renowned for its outstanding comprehensive performance, is widely adopted in new energy vehicles, power tools, home appliance motors, and industrial servo systems. Below, Fu from NST, a magnet manufacturer, introduces its features, advantages, and typical applications.

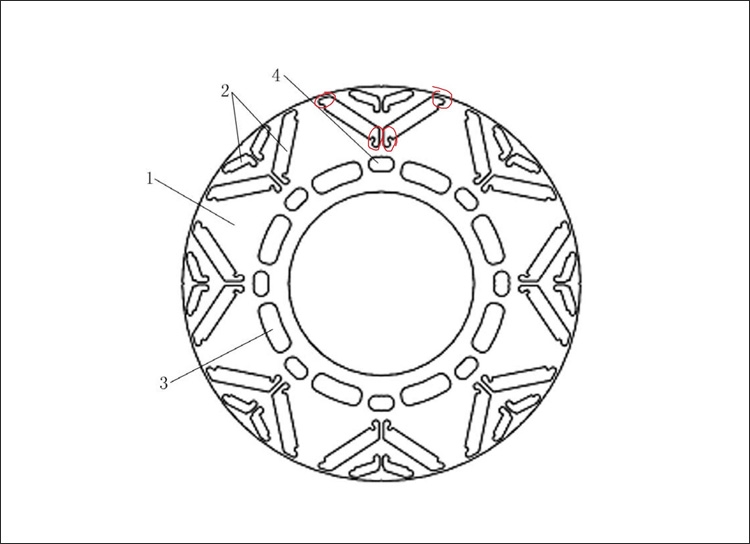

The V-shaped structure magnet rotor is a type of embedded permanent magnet rotor. Its magnets primarily consist of high-performance neodymium iron boron magnets (H/SH/UH/EH grades), embedded in a “V” configuration within the rotor core. Magnetic bridges are positioned between the magnets and on the outer sides to enhance mechanical strength and regulate the magnetic circuit. This configuration creates an angle between the magnets and the rotor core, enabling simultaneous output of both reluctance torque and permanent magnet torque.

Schematic Diagram of V-Shaped Structure Magnetic Steel Rotor

The core advantages of the V-shaped permanent magnet rotor structure lie primarily in its comprehensive performance and engineering adaptability. Building upon permanent magnet torque, this design fully utilizes the rotor's reluctance difference to generate reluctance torque, achieving the superposition of magnetic field torque and reluctance torque. This enables higher torque density and stronger output capability within the same volume. Simultaneously, the embedded V-shaped magnet arrangement significantly increases the inductance difference between the d-axis and q-axis. This confers exceptional weak-field speed control capability at high rotational speeds, effectively broadening the high-efficiency operating range. It is particularly well-suited for new energy vehicles and high-speed motor applications. Regarding mechanical reliability, the embedded magnet design eliminates the risk of magnet ejection during high-speed operation, eliminating the need for complex external restraint structures. This enhances overall safety and long-term stability.

Applications: Leveraging its performance and reliability advantages, the V-shaped magnet rotor is widely adopted in new energy vehicle drive motors, industrial servo motors, robotic joint motors, and high-speed, high-power-density PMSM systems.

The above provides an overview of V-shaped structure magnetic steel rotors. Should your company require pricing for motor rotor magnets or sample production, please feel free to contact our website customer service.

Common shapes of magnets used in motor rotors;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier