Brushless motors are renowned for their high efficiency, low noise, and long service life. However, if the permanent magnets (magnetic steel) inside become detached, it not only causes significant performance degradation but may also lead to severe consequences such as stator scratches, motor jamming, or complete failure. Therefore, timely identification of magnetic steel detachment signs is crucial. Below are the indicators of magnet detachment in brushless motors and corresponding preventive measures.

1. Abnormal Motor Noise

When the motor's magnets become detached or loose, the motor will emit abnormal noises during operation. These noises may manifest as high-frequency vibration sounds or unusual rattling. The noise becomes more pronounced under heavy loads or during startup. If such abnormal sounds are detected, immediately shut down the motor for inspection.

2. Increased Motor Vibration

When magnets become detached, the motor's rotor loses balance, potentially causing increased vibration during operation. Vibration not only compromises motor stability but may also accelerate wear on other components. Therefore, if noticeable vibration occurs during normal motor operation, inspect for signs of loose or detached magnets.

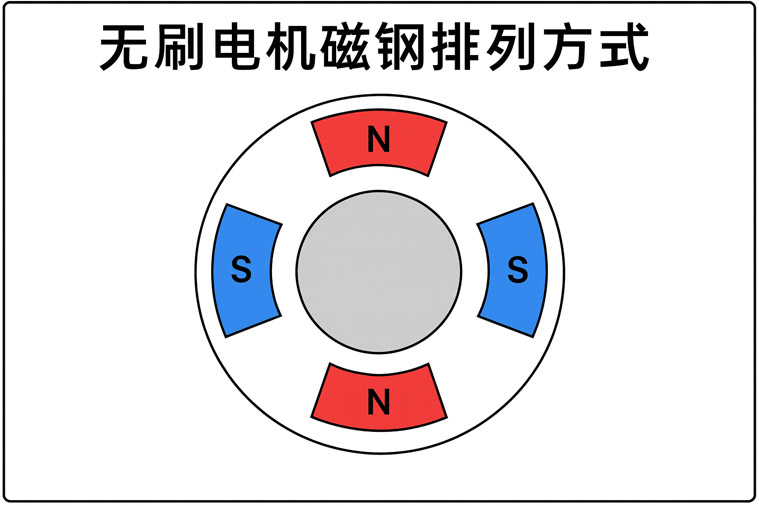

The accompanying illustration shows a typical arrangement of magnets in a brushless motor.

3. Decreased Motor Efficiency

Magnet detachment can cause a reduction in the motor's output power, manifesting as rough operation, diminished load capacity, or even failure to start. If the motor exhibits unstable power output or reduced efficiency during operation, it may be due to magnet detachment or damage.

4. Abnormal Temperature Rise

When magnets detach from a brushless motor, uneven current distribution may cause the motor to overheat. If the motor experiences an abnormal temperature rise during operation, especially without overload conditions, it may be necessary to inspect the condition of the magnets and other motor components.

To prevent magnet detachment issues, ensure the adhesive and bonding process are reliable, and properly control the motor's operating environment to avoid overloading. If damage, cracks, or aging of the motor magnets are detected during use, promptly replace the affected components. Particularly during motor operation, if any detachment or loosening occurs, immediately shut down the machine for inspection and perform repairs or replacements to prevent more severe failures.

Brushless Motor Magnet Product Selection;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier