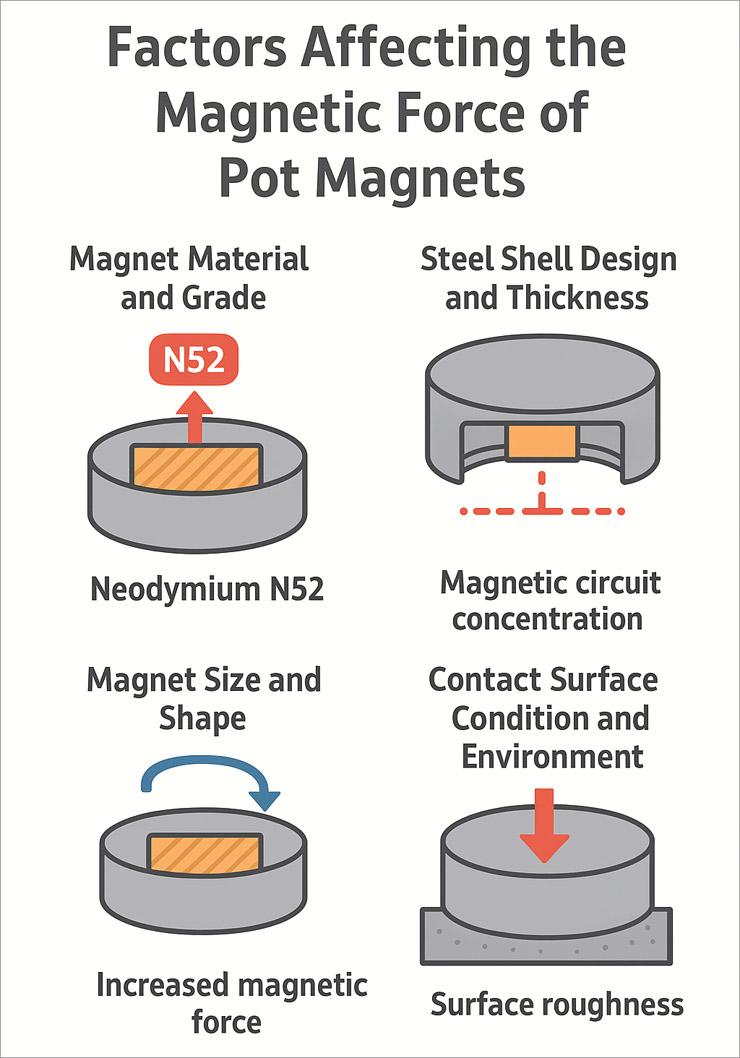

The magnetic force of pot magnets (also known as cup magnets or steel-cased magnets) is referred to as pulling force, representing the maximum pulling force achievable by the magnet. This pulling force is typically measured using high-quality low-carbon steel plates of predetermined thickness. Below are what we consider to be the 5 most significant influencing factors.

1. Magnet Material and Grade

This factor has the most significant impact. Ferrite pot magnets differ substantially from neodymium pot magnets, and the magnetic grade also greatly affects magnetic performance. Higher grades yield greater magnetic energy product (BHmax), resulting in stronger magnetic force within the same volume.

Factors Affecting the Magnetic Force of Pot Magnets

2. Magnet Size and Shape

The larger the magnet's volume, the greater the magnetic energy it stores internally, resulting in stronger magnetic force. For pot magnets, the ratio between the magnet and steel shell also matters. If the magnet is too thin, magnetic flux will be insufficient. If it's too thick, magnetic flux cannot fully pass through the steel shell for release, leading to waste instead.

3. Steel Shell Design and Thickness

The steel shell surrounding the pot magnet serves to “concentrate the magnetic path.” It channels magnetic force that would otherwise leak into the air from one side of the magnet and directs it toward the working surface, thereby significantly enhancing magnetic adhesion. A thicker steel shell facilitates more efficient magnetic conduction and greater magnetic concentration.

4. Contact Surface Condition

The magnetic force of the pot magnet is directly related to the surface condition of the iron object it adheres to. If the contact surface is uneven, coated with paint, rusted, dusty, or has gaps, it will reduce the effective magnetic flux.

5. Temperature

Temperature significantly affects pot magnets, particularly in high-heat environments where magnetic strength may weaken or even result in permanent demagnetization. If the application requires operation at temperatures exceeding 80°C, select high-temperature-resistant neodymium-iron-boron grades or consider substituting with samarium-cobalt (SmCo) magnets.

The above is the complete introduction of the article. High grade magnets, reasonable steel shell thickness, appropriate magnet size, and good contact surface are necessary to exert the strong suction force that pot magnets should have.

Additional information about pot magnets;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier