Permanent magnet rotor is one of the indispensable core components in modern motor technology, especially widely used in high-efficiency, energy-saving and lightweight drive systems. Today's article will focus on the definition, materials, advantages and application areas of permanent magnet rotors.

What is a permanent magnet rotor?

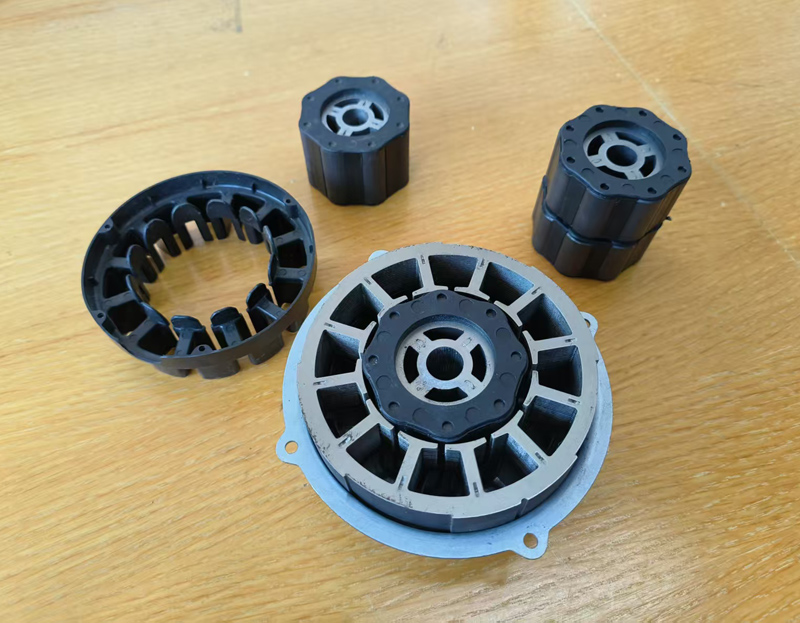

Permanent magnet rotor is a permanent magnet (such as neodymium iron boron, ferrite, samarium cobalt, etc.) mounted on the rotor part of the motor to generate a constant magnetic field, which is electromagnetically coupled with the stator windings, thus realizing the energy conversion and operation of the motor. Common shapes include rectangular block (surface mount), curved piece (surface mount or built-in), arc shape (surface mount), bar shape (built-in), and so on.

Picture shows 8-pole ceramic ferrite magnet rotor assembly.

Magnet materials for permanent magnet rotors

1. Sintered NdFeB

Currently the highest magnetic performance of permanent magnet materials, widely used in high-performance motors. However, its temperature resistance and corrosion resistance is poor, need to do plating treatment (such as nickel plating, zinc plating, epoxy resin, etc.) and select the high temperature resistance grade.

2. Samarium Cobalt

Higher magnetic energy product (second only to NdFeB), excellent high temperature performance (Curie temperature up to 700-800°C), good temperature stability, corrosion resistance, suitable for military, aerospace, high-speed machine tools and other high-end occasions.

3. Ferrite

Low cost, no rare earth, but relatively weak performance, suitable for cost-sensitive products such as fans, washing machines, etc.

4. Injection molding NdFeB or injection molding ferrite

Complex shapes can be realized by one-piece molding, suitable for motor products with small volume and high precision requirements.

Advantages of permanent magnet rotors;

High efficiency: no excitation loss, higher energy efficiency;

Compact structure: suitable for miniaturization and lightweight design;

Fast response: large starting torque, good dynamic performance;

Low noise and vibration: low rotor inertia, which is conducive to reducing mechanical noise.

Application Areas of Permanent Magnet Rotors

New energy vehicles: drive motors (the core power source of most electric and hybrid vehicles).

Industrial automation and robotics: servo motors, spindle motors, linear motors.

Household appliances: inverter air conditioning compressor, inverter refrigerator compressor, high-efficiency washing machine motor, high-efficiency fan.

Consumer electronics: hard disk drive spindle motors, drone motors, power tools (high-end).

Wind power generation: direct-drive or semi-direct-drive permanent magnet synchronous generators (especially in the field of high power).

Industrial high-efficiency motors: Replacement of traditional induction motors for significant energy savings.

Aerospace: actuators, flight control motors, auxiliary power systems (requiring high reliability and high power density).

Medical equipment: Precision instrument drives.

The selection of the type of permanent magnet rotor and material needs to be weighed against the specific needs of the application (cost, performance, environment, reliability, etc.). For personalized permanent magnet rotors or to purchase various types of high-performance magnets, please contact professional manufacturer NST Magnets.

Related magnet rotor products;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier