Magnet dislodgement flying piece refers to the permanent magnet steel on the motor rotor due to poor fixation or glue failure, in the high-speed rotation is thrown out, the formation of high-speed flight of dangerous fragments, commonly known as “flying piece”.

Here are some possible causes and solutions about drone motor magnets falling off the flying piece;

1. Internal defects in magnets

Cause:Defects such as porosity, inclusions, micro-cracks, etc. exist during the production process, reducing the strength of the material.

Solution: Adopt high purity NdFeB (N52 grade or above) to ensure the magnetic energy area (>50MGOe). Introduce ultrasonic flaw detection or X-ray inspection to reject defective magnets.

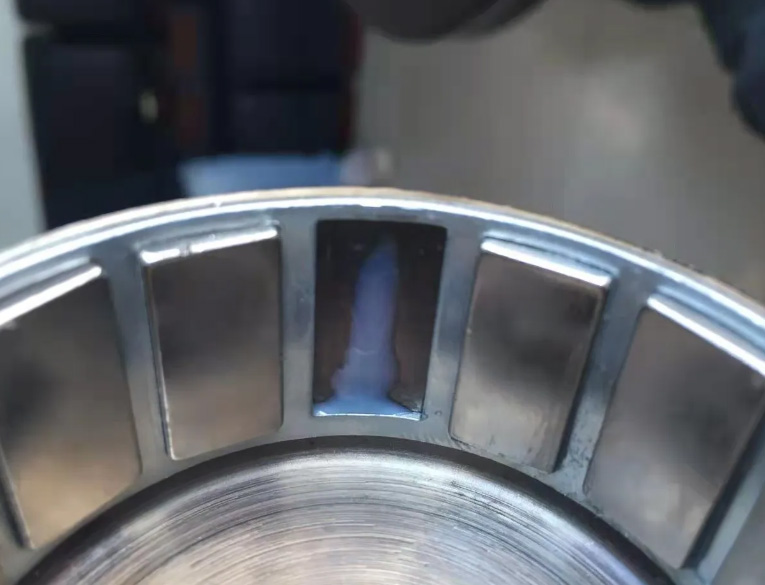

Magnetic steel (Neodymium Block Magnets) of the motor has fallen off

2. Insufficient thermal stability

High temperature magnet demagnetization or expansion coefficient does not match with the substrate (such as silicon steel and NdFeB CTE difference).

Solution: Use high-temperature resistant magnets (such as SH series, working temperature>150°C), magnet surface plating optimization (such as Ni-Cu-Ni composite plating to reduce thermal stress).

3. Centrifugal force exceeds the limit

The motor speed is too high (e.g. >50,000 RPM), the centrifugal force on the magnets exceeds the strength of the glue/fixing structure.

Solution: Optimize the magnet arc shaped design (reduce stress concentration), use high performance magnet bonding glue.

4. Defective bonding design

Uneven thickness of glue layer, insufficient contact area (<80%)

Solution: Optimize the path of glue application (e.g. “double helix” dispensing, so that the adhesive coverage area ≥ 90%)

What else do you know that can cause magnets to shed flying pieces?

Highly relevant article;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier