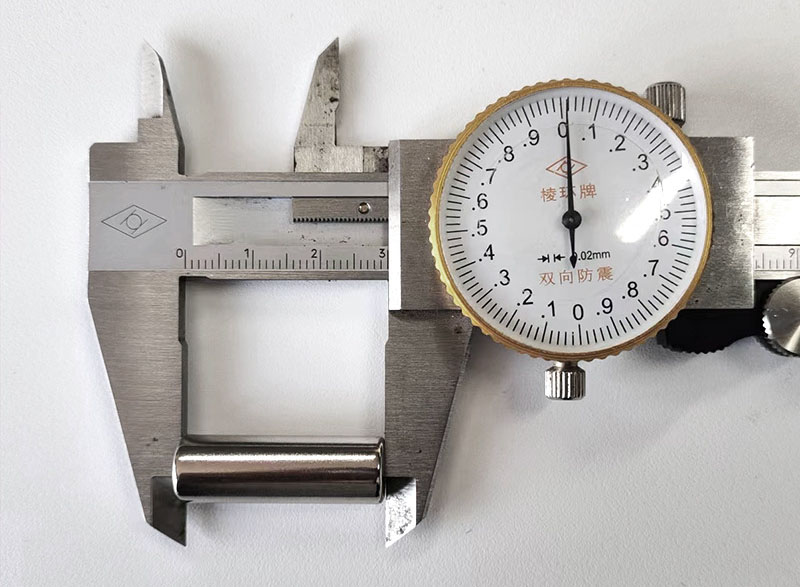

Neodymium rod magnet is a diameter less than the thickness (height) of a type of permanent magnets, customers often ask some questions when choosing or purchasing, the following is a xiaofu collated 10 consulting the frequency of high problems.

Typical neodymium rod magnet profile picture, the height dimension in the picture is 30mm.

Q1: What are the magnetizing directions for neodymium rod magnets? How to choose?

The common magnetizing directions for neodymium cylindrical magnets include axial magnetization (thickness direction) and radial magnetization (diameter direction). Axial magnetization is used when the magnetic poles need to be distributed at both ends (e.g. to attract flat objects). Radial magnetization is used when side fields are required (e.g. motor rotors, sensors or magnetic drives). The choice depends on the application.

Q2: How do I measure the Gauss value of a rod magnet?

Measurement using a Gaussmeter is axially magnetized to measure the center point of the smooth surface at both ends and take the highest value. Radial magnetization moves the Gaussmeter smoothly along the side of the cylinder and records the peak value.

Q3: What is the maximum size limit for neodymium rod magnets?

Conventional cylindrical magnets can be up to 300mm in diameter (depending on the supplier process) and some combinations of magnetic bars can be up to 1000mm.

Q4: What is the price difference in performance between different grades (e.g. N35 vs. N52)?

The higher the magnetic performance grade (e.g. N52), the higher the magnetic energy product and the stronger the suction force. the cost of N52 material is about 30%-50% higher than N35 due to the addition of more rare earth elements and optimization of the process.

Q5: What is the minimum order quantity (MOQ) and sample policy?

Support single item minimum order, sample delivery time is usually 5-10 days, and sample fees can be deducted in subsequent bulk purchases.

Q6: Can you customize rod magnets in specific sizes?

Of course you can. We support customized size and shape, such as slotting, side drilling and other special processing.

Q7: How do I mount a rod magnets? What kind of glue do I need to use?

It is recommended to use strong structural adhesive, instant adhesive or epoxy adhesive. The contact surface should be cleaned during installation to avoid metal dust and oil.

Q8: What plating is available on the surface of neodymium rod magnets?

Nickel-copper-nickel (NiCuNi): most commonly used, silver-white appearance, suitable for most applications. Zinc (Zn): economic, slightly weaker corrosion resistance. Epoxy (Epoxy): black or gray, suitable for humid or salt spray environments. Special plating such as gold/silver/plasticized: used for crafts, luxury goods or medical applications.

Q9: What are some common applications for neodymium rod magnets?

Sensor and Hall element matching, motor rotor or positioning mechanism, magnetic toys, furniture door sucker, nail art, magnetic connecting parts, etc. .......

Q10: What do I need to pay attention to when using neodymium rod magnets?

Keep away from high temperatures, strong reverse magnetic fields, and select the appropriate plating to prevent oxidation.

If you need wholesale/customized neodymium cylindrical rod magnets, inquire about issues not mentioned or other, please feel free to send us an inquiry.

Related cylindrical magnet products;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier