In the application of neodymium magnets, there are many scenarios that require the magnets to be glued together with plastic for use, today this article will introduce you to the step-by-step method of bonding neodymium magnets to plastic surfaces.

Step 1: Choose the right glue

The bonding of neodymium magnets to plastic requires consideration of the adhesion, temperature resistance and compatibility of the glue to the plastic. Recommended epoxy resin glue (AB glue), cyanoacrylate glue (instant glue/quick-drying glue), UV curing adhesive (need to be cured by ultraviolet radiation).

Ordinary 502 adhesive or hot melt adhesive is not recommended, the former is easy to embrittle, the latter poor temperature resistance.

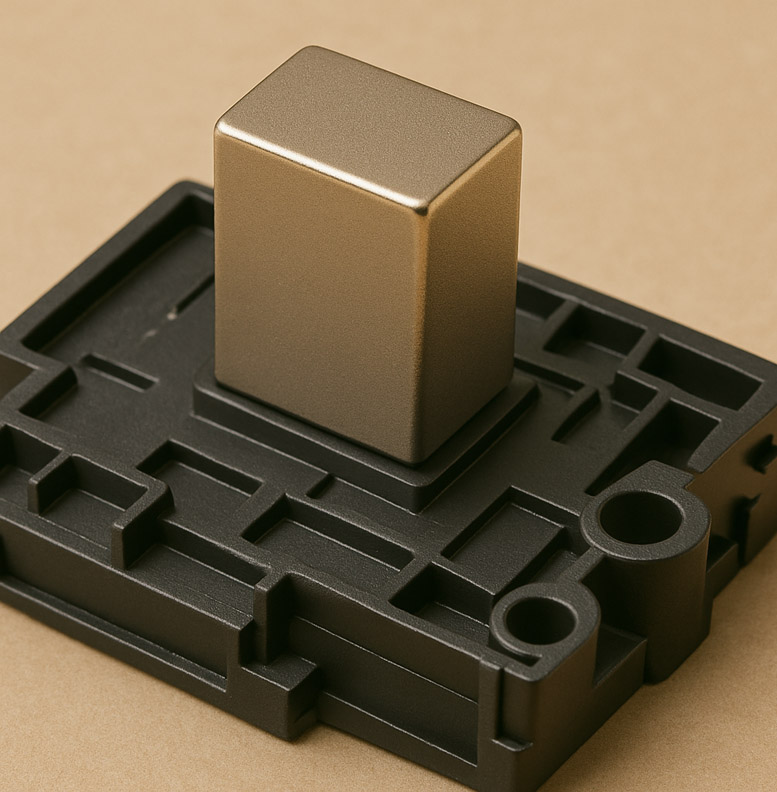

Rare earth neodymium block magnets bonded to plastic

Step 2: Wipe down magnets and plastic surfaces

Dip a dust free cloth in alcohol and wipe the magnet and plastic surfaces to remove grease and dust.

Step 3: Apply glue

Operate according to the type of glue, apply the glue to the magnet or plastic side, do not over apply the glue, so as not to overflow to affect the aesthetic or affect the magnetic force. Some glues don't cure that fast and need to be fixed by clamps or other objects to prevent shifting.

Step 4: Testing

It is recommended to test the use of the product after it has fully cured to ensure bond strength.

Suggested solution:

Recommend epoxy resin adhesive (high strength, good temperature resistance). Precise positioning can be achieved using UV glue (requiring a UV light source). Quick bonding can also consider instant adhesive, with a typical example being 502 (which has the disadvantage of not being resistant to high temperatures and moisture).

Note: We only sell magnets, we do not offer glue for sale!

Related magnet types;

Self Adhesive Neodymium Magnets [Disc Square Ring]

Other neodymium magnets fixed introduction;

What kind of glue is better for motor magnets?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier