The magnetic circuit is similar to the circuit, the magnet and the power supply are analogous, only increase the thickness, the flux corresponding to the residual magnetism is unchanged, but the internal reluctance becomes larger, when the external magnetic circuit reluctance is unchanged, the flux of the external magnetic circuit becomes larger.

About demagnetization: the magnet corresponds to the increase of magnetic kinetic potential, the internal magnetic resistance increases, the flux is small under the same demagnetization potential, and the demagnetization resistance is strong.

Weak magnetic properties such as demagnetization analysis, weak magnetic difficulties. On the other hand, d-axis magnetoresistance is large, Ld is small and weak magnetization is difficult.

Reverse potential increases, torque coefficient increases, copper consumption decreases, iron consumption is not good.

Cost increase is serious.

Cogging torque: breath magnetic density waveform is unchanged, the magnetic energy to the angle of the conductivity increases, the cogging torque increases.

Reverse potential waveform: generally speaking, the tooth part of the magnetic density saturated with the third harmonic, the reverse potential waveform flattens, torque fluctuations increase.

Find a motor model, ipm structure, parameterized motor magnet steel thickness, the performance is as follows:

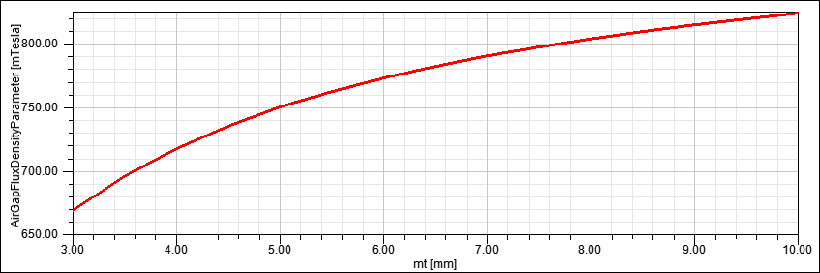

Air gap density with magnet thickness variation relationship

The air gap magnetization increases with magnet thickness, but not linearly.

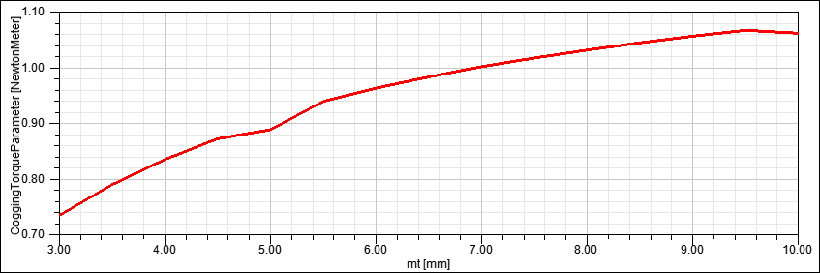

Cogging torque;

Tooth torque increases due to air gap magnetization enhancement. Tooth torque increases due to air gap magnetic density enhancement.

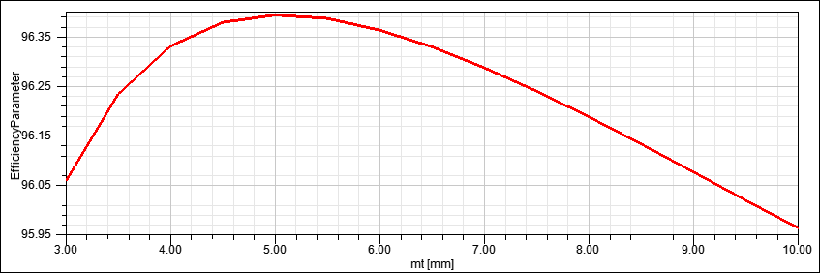

Efficiency;

Efficiency;

In this example, the output torque is fixed and the iron consumption increases faster than the copper consumption decreases when the magnet is increased.

Maximum output power;

The thicker the magnet, the greater the maximum output power capability.

Magnetic density of stator teeth;

Tooth magnet density increases as it should.

The d-axis inductance decreases with increasing magnet thickness.

Test Data;

From the actual test data: the increase in magnet thickness increases the performance at both low and high speeds.

The scenarios are as follows:

Option 1: Stator core thickness = Rotor core thickness = Magnet thickness (Stator core and rotor core thickness are the same)

Scheme 2: stator core thickness = rotor core thickness -5mm = magnet thickness -5mm (rotor core than the stator core thickness increased by 5mm, other test conditions remain unchanged, the measured motor torque at low and high speeds have increased (temperature rise and heat is not measured).

As a key component of the motor, the magnet affects the performance of the motor. The thickness of the magnet affects the motor's magnetic flux density, magnetic flux and reluctance and other factors, thus affecting the motor's torque, efficiency, power output and other performance parameters.

The effect of magnet thickness on magnetic flux density: the thickness of the magnet has a direct effect on the magnetic flux density, the greater the magnetic flux density, the greater the torque of the motor. Therefore, under the same power and current, a thicker magnet will produce a higher torque.

The effect of magnet thickness on magnetic flux: Magnetic flux is the size of the magnetic flux generated by the motor, which is affected by the magnet area and thickness. As the magnet thickness decreases, the magnetic flux decreases and therefore the efficiency of the motor decreases.

The effect of magnet thickness on reluctance: the thickness of the magnet affects the reluctance, the smaller the reluctance, the easier the flux of the motor can be transmitted through the magnetic boundary, the larger the torque and the higher the efficiency. In mechanical design, minimum reluctance is one of the key points for design optimization. Therefore, the impact of different thicknesses of the same grade of magnets is practical, and different magnet thicknesses can lead to significant changes in the performance of the motor, with an extremely dramatic impact.

Motor magnet selection;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier