Permanent magnet is an important material widely used in various industries, it has a variety of materials, performance, size, specifications, appearance, basically come to us to buy magnets for our customers need the size and other properties are different, it's some require thin, some require thick, so what is the optimal thickness of permanent magnets? Today's article lists some applications suitable thickness, hope to help you.

The optimal thickness of permanent magnets in motors and generators:

Generally around 5-15 mm, can be selected according to the size of the motor, speed, power and other parameters, thicker permanent magnets can provide a stronger magnetic field, but too thick will increase the mechanical inertia and cost.

Optimum thickness of permanent magnets in magnetic separators and filters;

Magnets are used to separate ferromagnetic contaminants from fluids or powders, and the optimum thickness is usually in the range of 10-30 millimeters, depending on the size of the separator and the required magnetic field strength.

Optimum thickness of magnets in magnetic adsorption equipment;

The optimum thickness is usually between 5-20 millimeters, this depends on the requirements for adsorption, too thin may not be able to absorb.

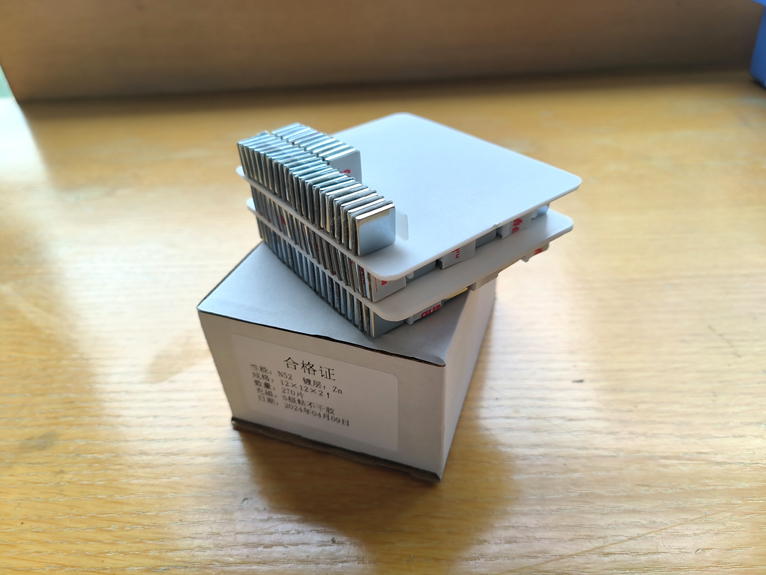

Rare earth neo square magnets with self-adhesive backing

Optimum thickness for permanent magnets in magnetic sensors and switches;

Usually between 2-10 mm, ensuring that the magnetic field strength is sufficient but not too large.

Optimum magnet thickness in horn speakers;

Typical horn magnet thicknesses are typically in the 5-25 mm range, with smaller sized speakers being able to use magnet thicknesses of 5-10 mm to meet the most basic drive force requirements. Medium to high power horns will require thicker magnets (10-25 mm) for adequate sound pressure output and low frequency characteristics.

What is the optimum magnet thickness in the packaging sector?

The main role of magnets in packaging is to provide magnetic attraction, large volume, and more sensitive to the cost, with NdFeB material then the thickness is generally better in the range of 0.5-2mm.

The above is the introduction of the best thickness of permanent magnets in each application, need to be tested and optimized according to the actual situation.

More permanent magnet thicknesses are presented;

Are magnets usually magnetized by thickness?

Analysis of the role of magnet thickness on motor performance

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier