Brushless motors use permanent magnet as one of their key components. These magnets usually use high-performance permanent magnet materials, such as rare earth neodymium strong magnets, mainly arc-shaped, fan-shaped, wedge-shaped, and rectangular. Today, this article mainly introduces the temperature requirements of brushless (DC) motor magnets.

In general, the temperature requirements of brushless motor magnets are as follows:

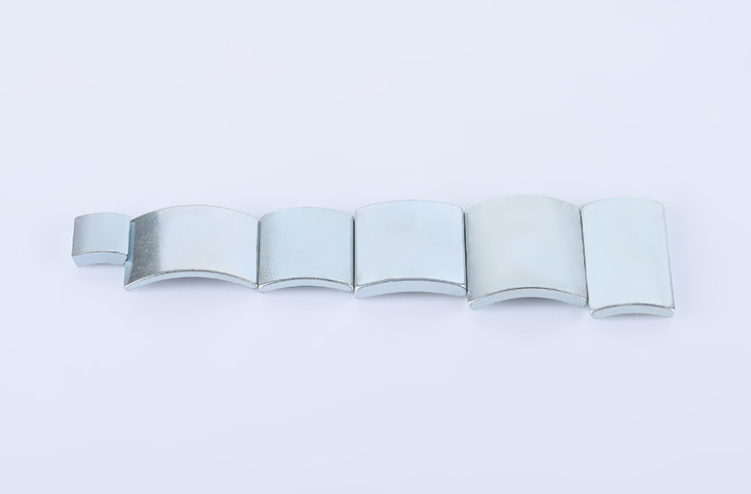

The following figure shows a variety of radians, string width, shaft length, thickness of neodymium curved segment magnets;

Operating(working) temperature: the temperature resistance of the magnet in the brushless motor generally needs to be above 100 ℃. The relevant Neodymium magnet grades are N35-N52H (100-120 ℃), SH (120-150 ℃), UH (150-180 ℃), EH (180-200 ℃)

Thermal stability: the magnet should have good thermal stability, that is, it can maintain high magnetic properties at high temperatures for a long time. This is very important for the long-term reliability of brushless motors.

Thermal expansion coefficient matching: In brushless motors, the magnet and other parts of the motor are usually fixed together, so the thermal expansion coefficient of the magnet should be matched with other materials to avoid stress and rupture when the temperature changes.

Low temperature performance: In some applications, brushless motors may be exposed to extremely low temperatures, such as in refrigeration equipment or polar detectors. In this case, the magnet should have good low temperature performance to maintain stable magnetism.

For specific brushless motor applications, it is recommended to refer to the technical specifications provided by the motor manufacturer or consult their engineers to understand the temperature requirements and limitations of the magnets used. Different types and grades of magnets may have different temperature properties, so it is important to ensure that the appropriate magnet material is selected to meet the needs of the application.

If you need to buy curved magnets for brushless DC motor, multi-pole ring magnets, we can provide you with relevant help, our customers are mainly motor, sensor based, in the magnet industry for more than 14 years, looking forward to your consultation.

Hot brushless motor magnet type;

Brushless motor skew arc neodymium magnet [custom supplier]

Brushless motor 10 pole ring neodymium magnet 45.9x41.4x13mm

Organize relevant articles on brushless motor magnets;

Advantages and disadvantages of three kinds of structure of brushless motor rotor magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier