Arc segmented permanent magnet is a very common magnet shape in the motor, today mainly to introduce the more concerned about the motor permanent magnet segmentation of several issues.

1, Permanent magnet motor arc segmented magnet if each section is not the same length what will happen?

This should be divided into specific cases, depending on the circumference of the index is not the same or axial thickness is not the same? If the circumference of the index is not the same certainly can not, will lead to the number of poles of the motor as well as each pole flux is not the same, which is not allowed and is not necessary. If the magnetic tile axial size is not the same is possible, anyway, in the core length of the arrangement of the full can be.

2, Segmented arc magnet way in the end what is the impact on the motor?

Segmentation is mainly to reduce the eddy current loss of permanent magnets, the original is a piece of the whole, just like the principle of slotting is the same.

3、What is the impact of the number of segments of permanent magnets on the performance of the motor?

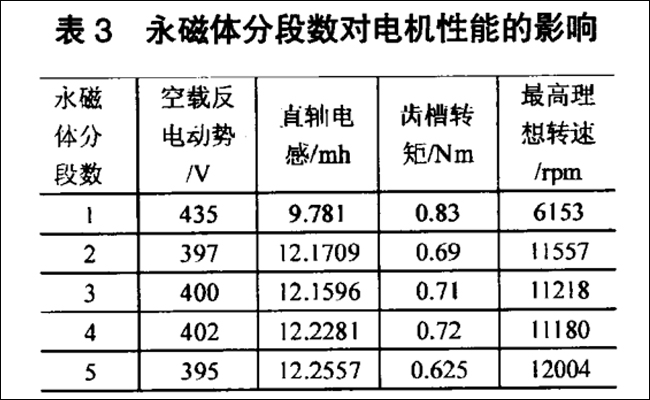

Permanent magnet segmentation number of different motor no-load reverse electromotive force, notch torque, straight shaft inductance, the highest ideal speed of the impact is not significant, there is no very obvious changes, there is no very obvious law.

Effect of the number of permanent magnet segments on motor performance

4, How to segment the motor magnet segmented inclined pole segmentation?

The segmentation method of the magnet steel segmented inclined pole is related to the performance and efficiency of the motor. Generally speaking, the magnet steel segmented inclined pole is divided into two ways: continuous segmentation and intermittent segmentation. Continuous segmentation refers to cutting the magnet into an oblique shape, but each block is still continuous, and the polarity of the two adjacent blocks between blocks of the same phase is opposite. Intermittent segmentation means that the magnet is cut into blocks that are independent of each other, but the polarity of each section is still continuous.

The segmentation method of magnet segmentation of slanted poles is also related to the slope parameters, such as slope angle and slope length, which can affect the performance and efficiency of the motor. The choice of slope angle and length should be determined according to the application and design requirements of the motor.

Written in the end: permanent magnet segmentation can indeed reduce the permanent magnet magnetic chain, strengthen the straight-axis armature reaction, reduce the loss of the motor, improve the efficiency of the motor, but the change in these properties and the number of permanent magnet segments has almost no relationship, but rather with the segmentation of the permanent magnets asked the sum of the width of the magnetic bridge, the material of the magnetic bridge between the neighboring permanent magnets and the rotor iron core are silicon steel sheet, due to saturation. The magnetic resistance of the magnetic bridge is much larger than that of the air gap, and the magnetic resistance of the permanent magnets is much larger than that of the magnetic bridge, so most of the main magnetic flux passes through the air gap, and most of the weak magnetic flux passes through the magnetic bridge, so that the motor's straight-axis armature reaction will be relatively enhanced, and the motor's alternating and straight-axis inductance are both increased, which is conducive to the improvement of the motor's weak magnetic capability, and at the same time, it can increase the range of constant power operation.

Arc Segmented Magnet Selection;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier