As a manufacturer of motor magnets, we frequently receive customer requests for sine wave multi-pole magnetic rings. Many people may not have heard of them before. Below, Fu from Carichi will introduce this type of magnetic ring, covering its primary materials, key advantages, and common applications.

A sinusoidal multi-pole magnetic ring is a multi-pole magnetized ring featuring magnetic poles distributed according to a sinusoidal pattern. Unlike the alternating N-S linear arrangement of traditional magnetic strips, its magnetic pole distribution exhibits a continuous gradient pattern resembling a sine wave, with magnetic field strength varying periodically along the ring's circumference.

What are its main characteristics?

Multiple pairs of N-S poles are arranged on a single magnetic ring (e.g., 4-pole, 8-pole, 16-pole configurations).

The magnetic field strength does not change abruptly but transitions smoothly like a sine curve.

In terms of material, sine wave magnetic rings commonly use bonded neodymium iron boron (high magnetic performance) or sintered injection-molded ferrite (low cost/high stability).

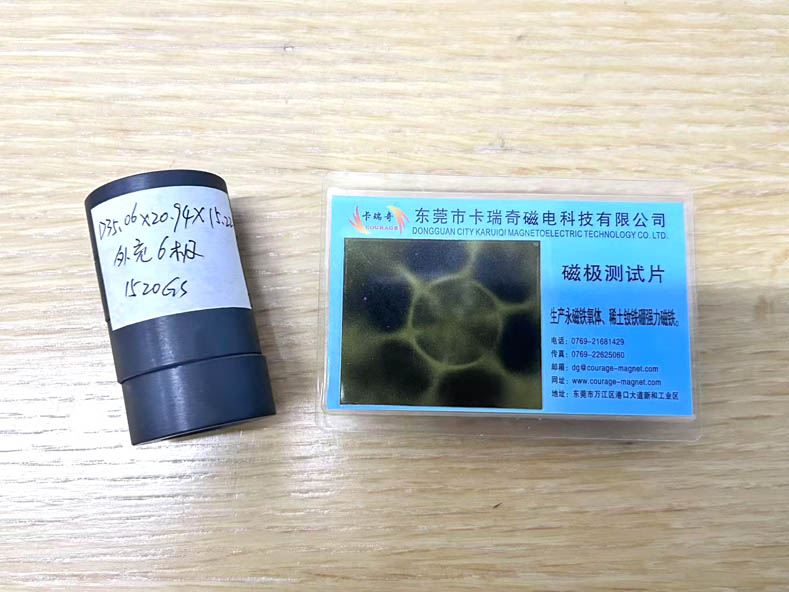

Illustration shows a 6-pole magnetized sintered ferrite ring with radial outer diameter.

What are the advantages?

Better signal quality, smoother operation, reduced vibration and noise, and higher precision.

Currently, these magnetic rings are widely used in brushless motor position detection, high-precision magnetic encoders, robotic joints/servos, precision instruments, and wheel speed sensors (ABS).

Multi-stage sine wave magnetic rings (special magnetization method) have become core components in modern high-performance sensing systems due to their high precision, low noise, and high-pole design. Should your company require purchasing these, please contact our website customer service for assistance.

Product recommendation;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier