Common magnet, generally referring to ceramic ferrite magnets, is a common permanent magnet material. It is widely used in various low-cost products due to its low cost, good magnetic properties, and corrosion resistance. So what is it made of?

The core component of ferrite magnets is iron oxide (Fe₂O₃, the main component of rust), which combines with other elements such as barium oxide (BaO) or strontium oxide (SrO) to form ferrite compounds. Their chemical formula is typically BaFe₁₂O₁₉ or SrFe₁₂O₁₉.

The main difference between strontium ferrite (SrFe₁₂O₁₉) and barium ferrite (BaFe₁₂O₁₉) is that strontium ferrite offers superior performance and is more environmentally friendly, but it is also more expensive. It is currently the mainstream choice and is widely used in automotive motors (such as fan motors, windshield wiper motors, and starter motors), high-performance small motors, and speakers that require higher magnetic performance (especially mid-to-high-frequency units), sensors, magnetic separation equipment, and other applications.

Manufacturing process: The raw material powder is mixed, pressed into shape, and then sintered at high temperatures (similar to firing ceramics). Strontium ferrite requires a higher sintering temperature (typically 1250-1300°C).

Some characteristics:

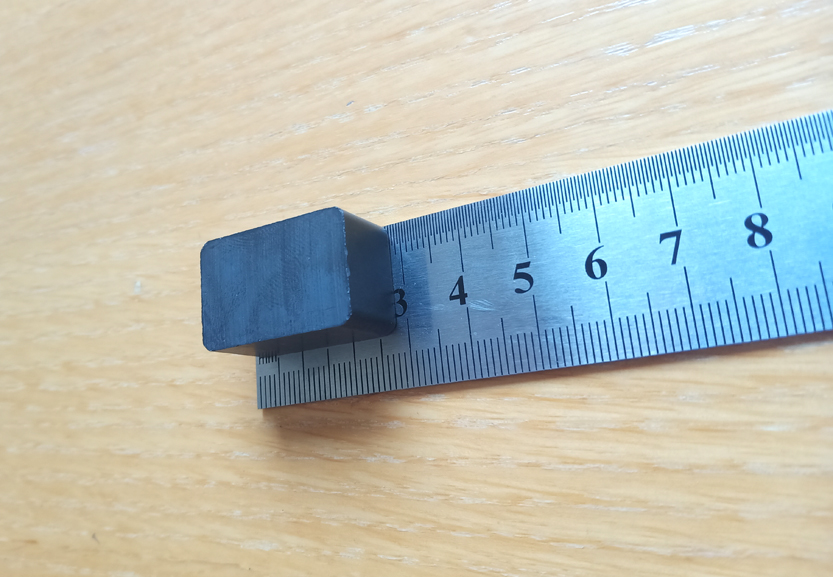

Dark gray or black in color, hard and brittle in texture, similar to ceramic.

Relatively weak magnetic properties (but sufficient for most applications), very low cost.

Highly corrosion resistant (does not rust easily).

Good high-temperature resistance.

Widely used in refrigerator magnets, speakers, small motors, toys, teaching aids, etc.

Ferrite magnets are a very important type of permanent magnet material. With their excellent magnetic properties, low cost, corrosion resistance, and temperature stability, they are widely used in many fields. Although their magnetic strength is not as powerful as that of rare earth permanent magnet materials such as neodymium-iron-boron and samarium-cobalt, they perform exceptionally well in many low-power, low-cost applications and remain an indispensable component in many electronic products and mechanical devices.

Introduction to other ferrite magnets;

Soft Ferrites vs Hard Ferrites Detailed

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier