Cars (auto) are almost irreplaceable in our lives, but did you know that magnets also have a non-negligible presence in car manufacturing? Do you know how many parts of a car use magnets? Or how many car motors use magnets? What are the main materials of car magnets? Today let's take a closer look at the importance of magnets in the automotive manufacturing process!

What meterial magnets will be uses in car part?

Many parts of the car are used in magnets, whether it is built-in parts, external parts or car decoration, there are magnets or magnets can be used to make these parts, products have greater value and effect. Automotive motors will basically be used in ferrite, but rare earth neodymium magnets, samarium cobalt magnets, rubber magnets will be used. Their main role is to produce magnetic fields and adsorption.

The application of car magnets:

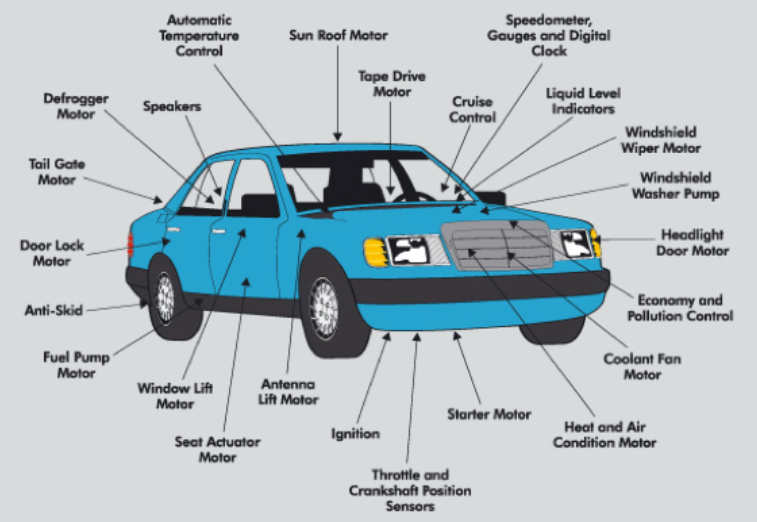

Over the past few decades, cars have changed from electromechanical control systems to complex electronic control systems. This is in contrast to the more widely used pneumatic, hydraulic and mechanical control systems of the past. This shift to electronic control of steering has greatly increased the need for magnets to support a variety of systems within vehicles, including sensors, drives, and motors.

There are many parts of a car that use permanent magnets

The following is an introduction to the use of ferrite magnetic tiles in automotive motors:

Front wiper motor

Rear wiper motor

Warm air machine

ABS motor

Starting motor

Condensing fan motor

Height-regulating machine

Seat motor

4 wheel drive anti-lock motor

Fuel pump motor

Power antenna

Purified fan motor

Electric skylight motor

Window motor, etc

In the automotive industry, magnetic applications are a key component of vehicle performance, safety and convenience. For example, ceramic ferrite magnets can be used in anti-lock braking systems (ABS) to improve driver safety and make roads a safe place for everyone to drive.

Neodymium magnets concentrate extremely high power into smaller magnets compared to other available magnet materials, making them an excellent choice for magnetic applications that require lightweight magnets or magnets that can be installed within a limited size. Many rearview mirrors are coated with neodymium magnets to avoid collision wear. Today, rare earth magnets are being used in electric vehicle drivetrains as an environmentally friendly way to improve vehicle efficiency without sacrificing performance.

Magnets are also used in many other vehicle mechanics, including transmission and oil pan chip collectors, fuel pumps, airbag actuators, steering sensors, dashboard instruments, and even speakers in automotive stereo systems. Magnetic sensors are perhaps the most compelling application of magnets. For example, whenever your low tire pressure light comes on, it's the result of a magnetic sensor, and whenever you turn on your windshield wipers, these motors are also powered by magnets.

The above is a brief introduction to the movement of magnets in the car, I hope to help you. We are Courage magnet manufacturer in China. We can customize magnets of various materials and shapes. If you have a need for a car magnet, please contact us and provide the required magnet requirements!

China Courage Magnet Manufacturer

China Courage Magnet Manufacturer

WeChat

Scan the QR Code with WeChat