Neodymium magnet machining mainly includes punching processing, cutting processing, in addition, there is a relatively advanced processing method, that is laser processing, today we will talk about what is laser processing, characteristics, applications.

Q: There is one cutting way is laser cutting, So NdFeb magnet can use laser cutting?

A: Yes! At present, there is a ndFeb laser cutting machine on the market can carry out laser cutting on NdFeb. According to the laser cutting technology, it not only improves the production efficiency, and the cutting precision (product consistency) also got a great boost. Compared with the traditional wire-cutting process, the production process and production time are greatly reduced by laser cutting, and made the industrialization and standardization of production are truly achieved.Strong magnets of different shapes can also be directly formed at one time, but there are not widely used by magnet manufacturers in the market.

According to the discussion of laser cutting of sintered NdFeb permanent magnet material: The cutting tests of products with different thickness show that laser cutting is suitable for products with thickness less than 6mm. When the thickness of the product increases, it is easy to have defects such as heat affected zone and blowing section, and there are quality defects in the products cut out.

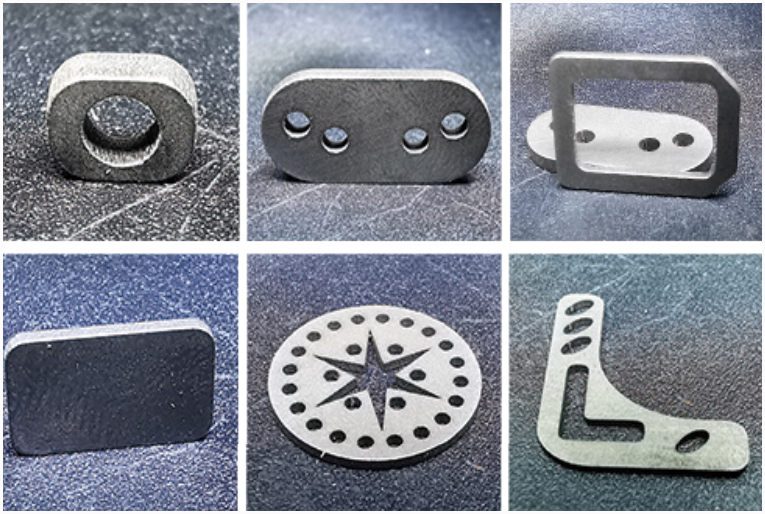

The image below shows a sample of laser cut neodymium magnet by NACI LASER.

Magnet laser machining has the following characteristics and applications:

Cutting and punching: Magnet laser cutting and punching can be used to make magnet parts or components. By controlling the energy density and focusing position of the laser beam, high precision, non-contact cutting and punching operations can be achieved. This is particularly important in magnet processing, because magnets usually have high hardness and magnetism, which may not be easy to achieve with traditional machining methods.

Surface modification: Laser processing can modify the magnet surface, such as surface melting, melting and cladding. This can change the physical and chemical properties of the magnet, improving its wear resistance, corrosion resistance and precision. Surface modification can also be used to make magnets with special shapes, such as bumps, depressions and microstructures.

Etching and marking: Laser etching and marking can be used to carve a pattern, text or logo on the surface of a magnet. This is of great significance in magnet applications, such as product identification, serial number, brand logo and so on. Laser etching and marking have the advantages of high precision, no contact and programmability.

In general, magnet laser machining is a precise and efficient machining method, which can be applied to the cutting, punching, etching and other aspects of magnet materials, It is widely used in various industrial fields

China Courage Magnet Manufacturer

China Courage Magnet Manufacturer

WeChat

Scan the QR Code with WeChat