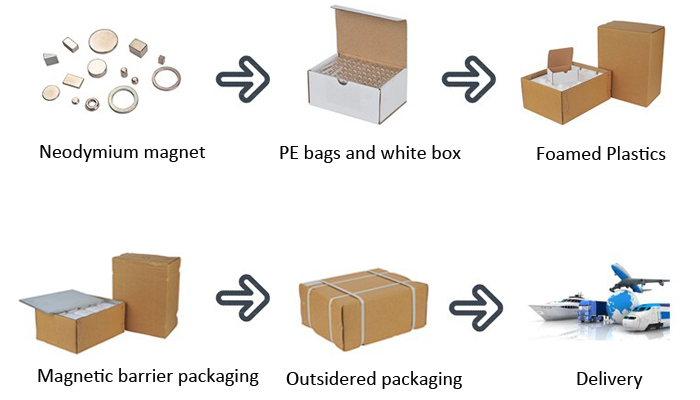

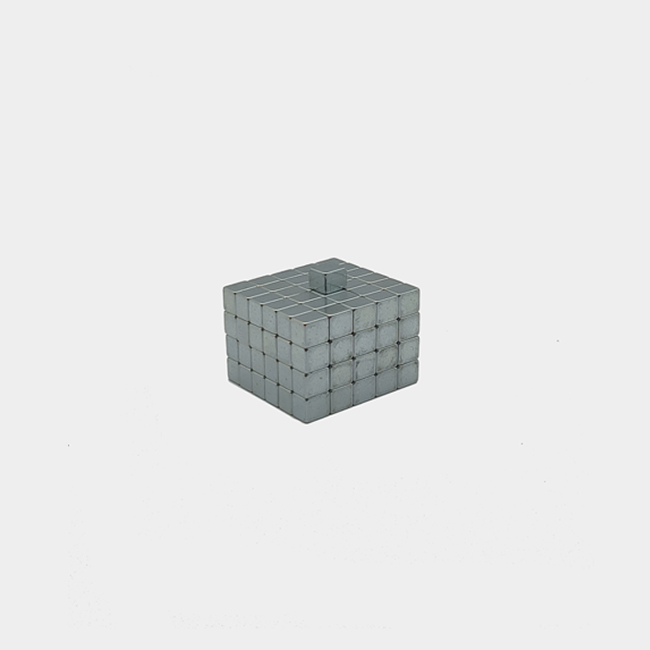

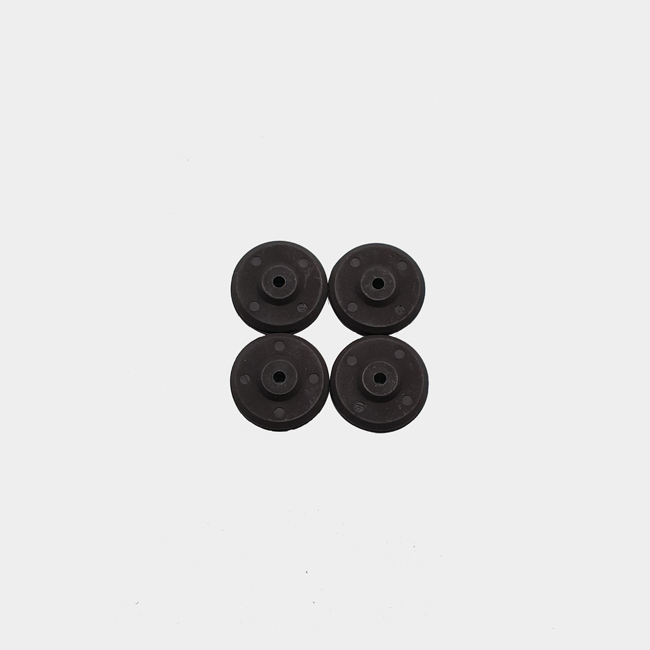

This is a radial 4-pole sintered ferrite magnetic ring provided by the manufacturer of Courage Magnet. The outer diameter of the magnetic ring is 35.8mm, the hole diameter is 15mm, and the height is 50mm. It is of medium size and is magnetized radially, with a surface magnetic field of 1500 Gauss. It is mainly used for various permanent magnet DC motors. If you need samples or want to know the price, please send us an inquiry.

D35.8 x 15 x 50 mm 4 pole sintered ferrite rotor magnet diameter size measurement;

Our company has a complete range of multi-pole ring magnet specifications, which can meet your requirements for axial multi-pole, radial multi-pole and oblique magnetization of magnets. We look forward to cooperating with you!

Other specifications 4-pole rotor magnet ring;

Radial hollow hole cylinder ferrite rotor magnets 20x6x45mm

Water pump 4 pole radial ferrite magnet rotor 14mm x 5.2mm x 28mm

China Courage Magnet Manufacturer

China Courage Magnet Manufacturer