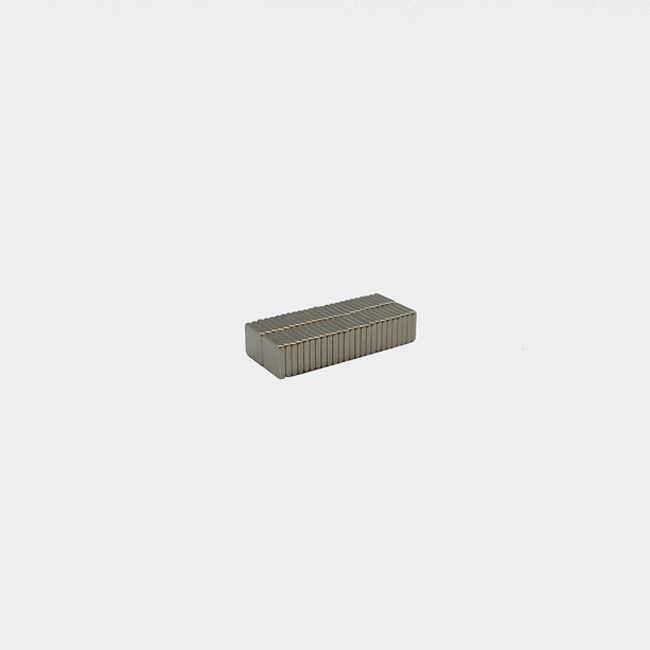

Rectangular countersunk magnet is popular for decoration and industry, the sample specific size of this magnet is 20mm in length, 10mm in width, 5mm in thickness. It is plated nickel with silvery white. The working temperature is 80℃, can reach 230℃ highest.

The magnet is very suitable for fixed furniture, countersunk head hanging artwork and keep doors and drawer shut down, the countersunk magnets have a sink hole, on both sides of the screw fixed on a non-magnetic surface can be used. Sinking magnets with opposite poles can be used to attract two surfaces, or two opposite sinking magnets with the same poles can be used to create resistance, reduce shock sensation or repulsion effects.

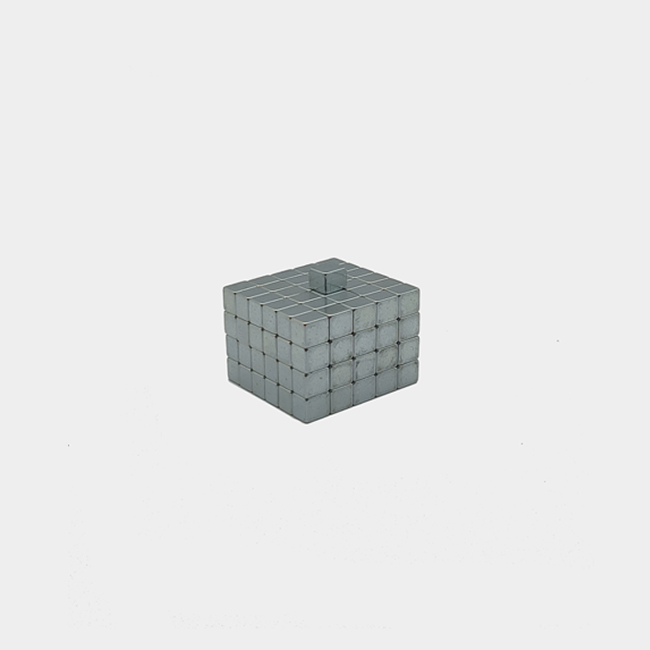

Application of 20 x 10 x 5mm Powerful rectangular countersunk magnet with one screw hole:

Door and window latch, automotive industry, electronics industry, IT information, medical equipment, mining equipment, industrial automation, sports equipment, power tools, electrical appliances, clocks, LED lighting, security equipment, bags and leather goods, hardware and plastics and other fields.

Related rectangular countersunk magnets articles;

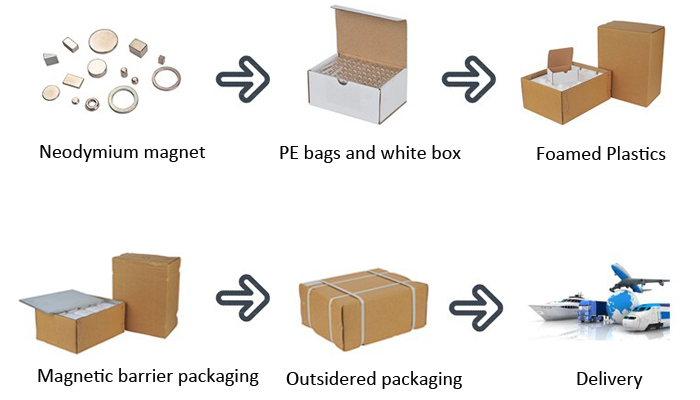

China Courage Magnet Manufacturer

China Courage Magnet Manufacturer